Welcome to Brand Breakdown, a series of comprehensive yet easy-to-digest guides to your favorite companies, with insights and information you won’t find on the average About page.

Most people around the world track time using the Gregorian Calendar, brought to public use in 1582 by Pope Gregory XIII, as it was (and remains today) far more accurate than previous calendars. In the Gregorian Calendar, leap years compensate for the Earth’s fractional 365.2425-day trip around the sun. Leap years effectively average out our years to a tidy 365 days, but even this system is not exact, because the actual solar year is 365.24667 days. Because of this slight inexactitude of the Gregorian Calendar, after 400 years our timekeeping ends up three days ahead of the sun’s actual rotation. So, we drop those extra three days by skipping the leap year every 100 years, meaning we only do this three times in 400 years.

You follow all that? Given the complex anomalies of our calendar, fashioning a tiny mechanical device that can track all of this information accurately is an incredible accomplishment. Timepieces that incorporate this information are called “perpetual calendars,” and it was Patek Philippe that led the development of fitting this feat of human engineering into small wristwatches.

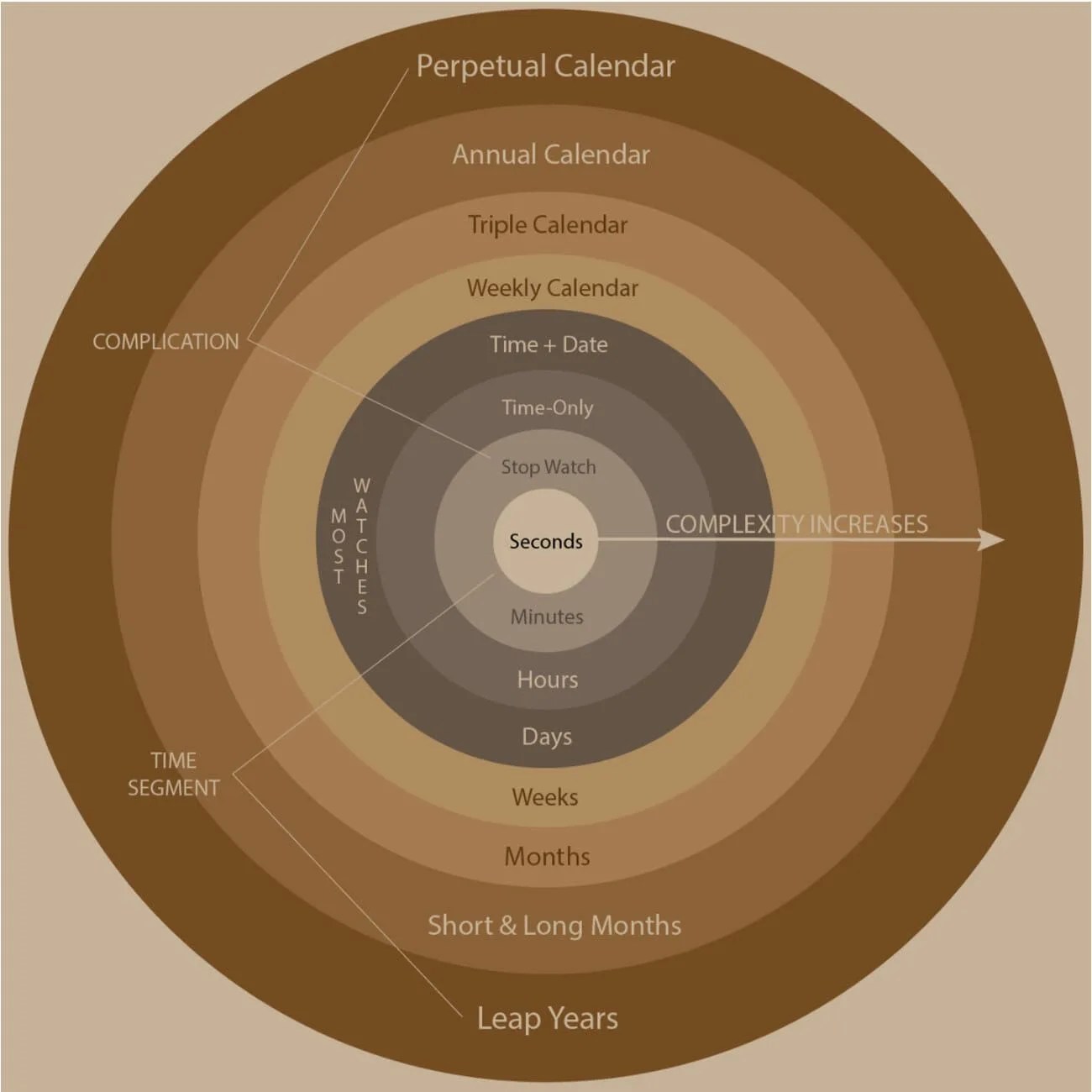

To better understand perpetual calendar watches, consider the following diagram. You’ll see that as watches extend the time interval that they track from seconds to minutes, all the way out to leap years, the complexity of the movement advances from the simplest mechanical timekeepers like stopwatches to the perpetual calendar, with a number of increasingly complex mechanisms in between.

Mechanical watches consist of a power source (the mainspring and barrel), the transmission that controls the rate at which the hands and other indicators move (the gear train), and a power distribution and regulation device (the escapement). To appreciate what goes into a perpetual calendar watch, we’ll focus on the gear train.

The mainspring (our power source) turns the barrel cog that drives the gear train. By varying the size of the subsequent cogs in the gear train, the ratios work out to produce the movement of the various hands that subdivide time into seconds, minutes, hours, days, and so on.