There are only two watch companies in the world considered to be fully and truly vertically integrated. One is Rolex. The other: Seiko. In case you find yourself tempted to compare Seiko to the Big R, really consider for a second the scale of Seiko’s operation. By one spokesperson’s estimate, Seiko makes about a third of the world’s watch supply — millions of watches that run the gamut from cheap quartz movements to jeweled tourbillons costing nearly half a million dollars. And Seiko makes all the parts for these timepieces: the cases, the dials and every aspect of the movement, even going as far as growing its own quartz crystals.

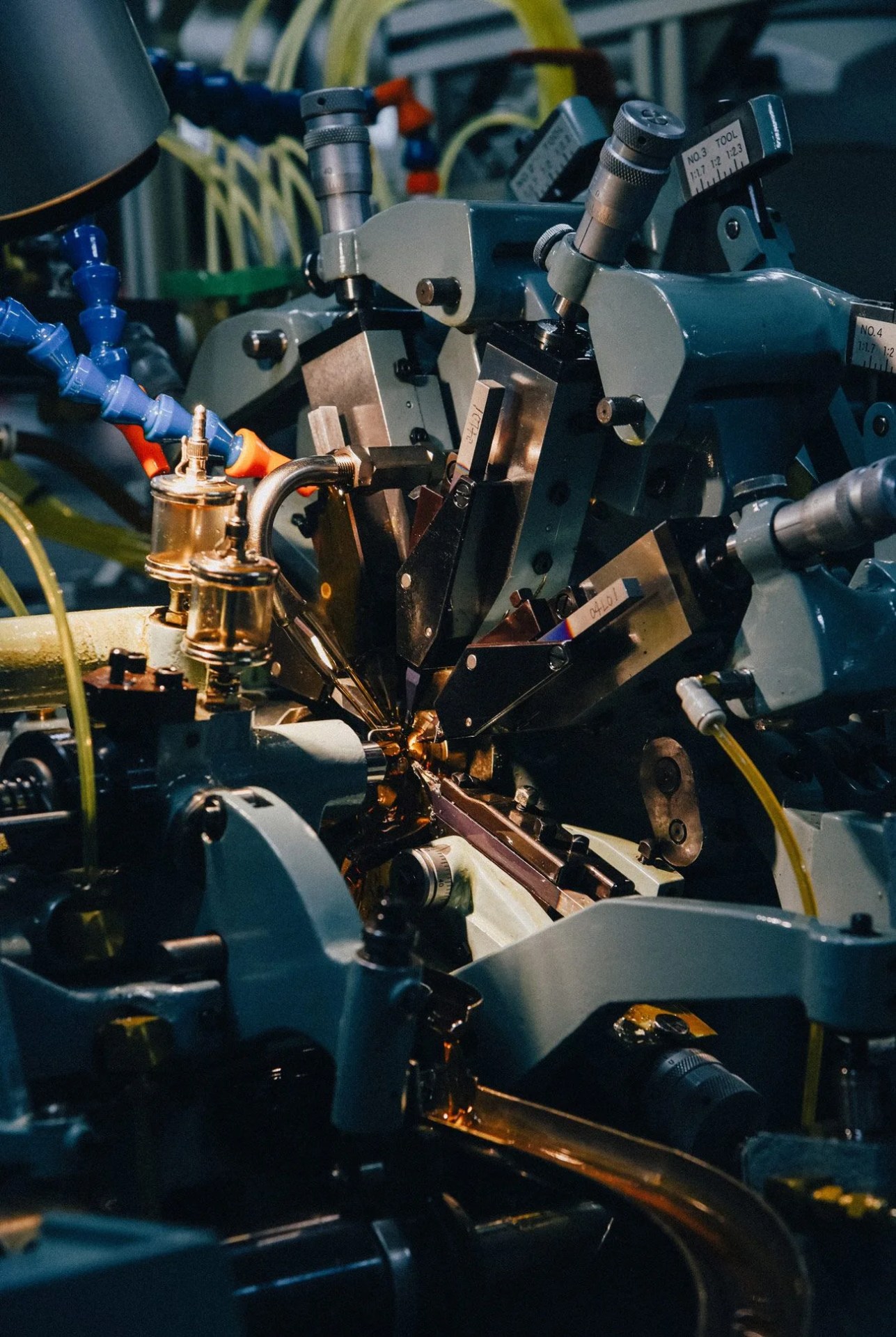

If the idea of a watch manufactured in-house impress a watch enthusiast, as it often does, Seiko’s operation should downright floor them. The company’s facilities are spread out to several locations across Japan and a visit to just one puts the diversity of the brand’s watchmaking mastery on full display. Cases are hand-polished in a room just down the hall from the space where some of the industry’s most unique dials are crafted; a handful of artisans finish the brand’s ultra-luxe Credor watches by hand in a workshop that’s below an assembly line that autonomously cranks out thousands of quartz movements a day.

Seiko’s expansive operation is a refreshing palate cleanser to those of many Swiss brands who tend to play up their country’s old-world association with watchmaking. The brand embraces the new as much as it does the old and employs both mass production and handcraft. In that respect, Seiko is an honest representation of watchmaking at every level.