It’s been 20 years in the making for one British brand but even longer for British watchmaking as a whole: The announcement that Bremont has made its first credibly “made-in-England” watch movement is big news in several ways. It’s a milestone not just for the company and for the country — which was historically the proud center of watchmaking before Switzerland — but also for the watch industry at large where many others dream of bringing watchmaking (back) to their home countries. Gear Patrol joined Bremont in London for the launch of the movements featured in the new Longitude limited-edition collection and to see the watches first-hand.

The new Longitude LE Collection comprises 40mm watches in three variants with a relatively classical look. Right out of the gate, these new automatic movements are equipped with a silicon escapement and offer more than basic time telling with a couple complications: a power reserve indicator (65 hours) and a digital date display (meaning each digit is displayed via its own wheel beneath the dial rather than a single disc showing 1-31). As is the case with any Bremont watch, their impressive build quality is easily appreciated in person.

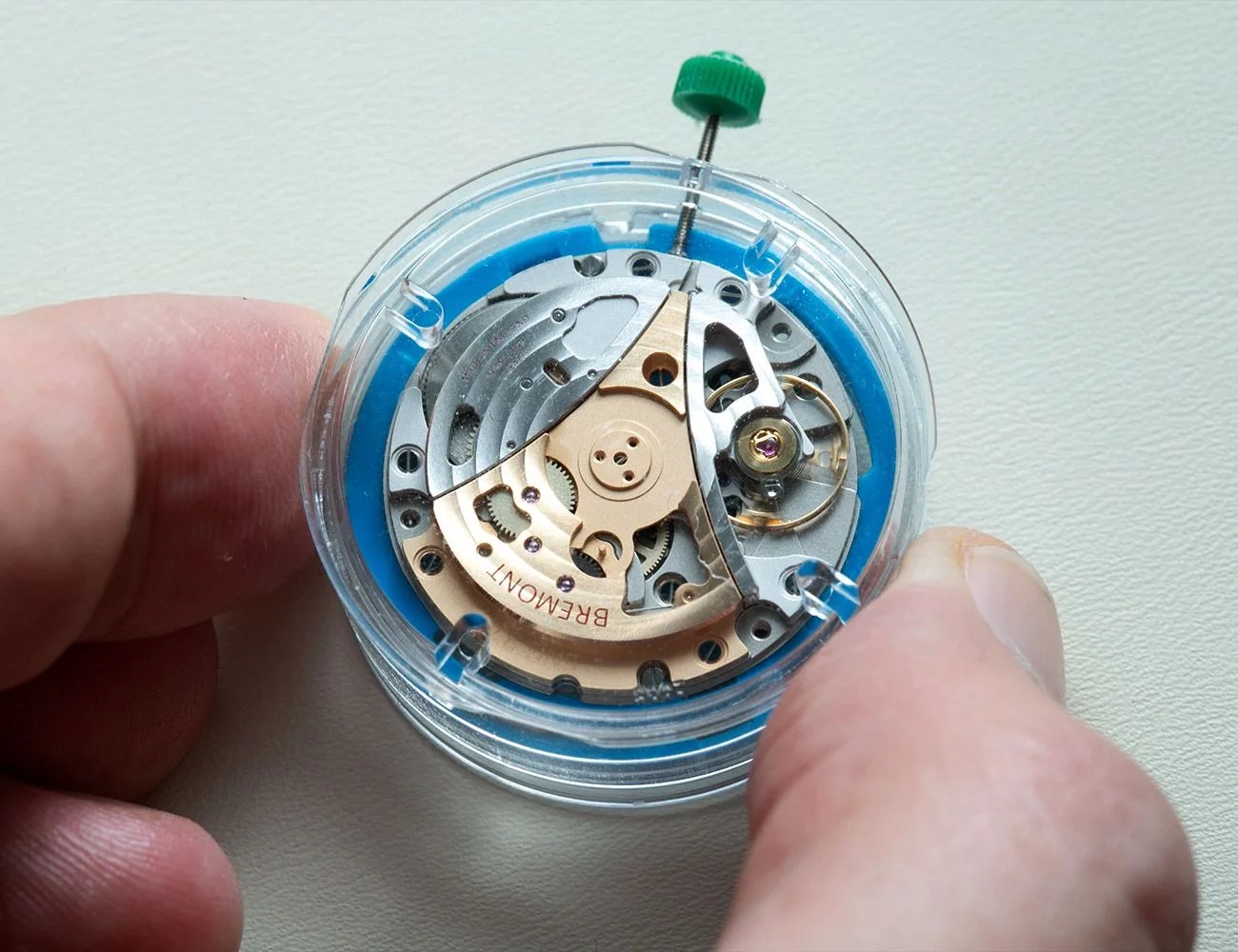

Turn them over, and you can see the interesting and nicely finished architecture of the Bremont ENG300 movement (ENG376, in this configuration), as it’s called, through the display case back. The collection that debuts these impressive movements represents the culmination of the brand’s mission since its outset, but they also mark a new beginning: Whether the prices or styling of this particular collection is to your tastes, the real news is that the movement is designed to be produced at scale as well as adaptable to accommodate everything from simple three-hand time telling to a range of complications — and you’ll gradually see them powering new and established collections alike without a big price increase from those that currently use sourced movements.

Why is it such an achievement for a company to make its own movement? Watch movements are complicated and incorporate hundreds of tiny, precise parts that require specialized skills and the capacity to manufacture. While many watch brands are proud to display a “Swiss Made” label (even if they’re not based in Switzerland), many more dream of making a watch that’s genuinely and completely Made in USA or Made in France, for example, and serially produced — but few countries outside of Switzerland, Japan, China and Germany have the resources to produce mechanical watch movements and their myriad intricate components domestically. The mere fact that others haven’t yet done it and that it took Bremont nearly 20 years to reach this point speaks to just what a challenge it is.