8 photos

Eisfeld is a sleepy village on the German Green Belt, population 6,000, dotted with cherry and beech trees, resting almost squarely on the former line of demarcation between East and West Germany. There is foliage, and open air, but the place has an industrial feel — it could be a hillside town tucked into the Steel Belt were it not for the fairytale German castle that peeks down on the warehouses. On the southern edge of the town sits one sprawling factory for a company called Feintechnik, now Harry’s, which has been making razor blades since 1920.

Feintechnik is a critical cog in Eisfeld’s commerce, employing over 600 people, and it comes with a storied history. It survived decades as part of the Eastern Bloc after WWII, then nearly went bankrupt in the ’90s before stumbling upon some technical innovations that kept it afloat through the aughts. And in this massive factory in a tiny town, Harry’s co-founders Jeff Raider and Andy Katz-Mayfield have found the key to growing their startup. And it started with a cold email in 2011.

“I personally didn’t have contact with them in the beginning, because I had work to do,” Vice Chairman of Harry’s Heinz Dieter Becker recalled with a laugh.

After Raider (who also co-founded Warby Parker) and longtime friend Katz-Mayfield decided to get into the shaving business, they tried countless razors with uninspiring results. Raider eventually found a shaving forum that recommended a five-blade shaving system called Croma, which was manufactured by Feintechnik. After shaving with the blade, Raider was sold. He told Katz-Mayfield they had to reach out to Feintechnik and attempt to forge a partnership. After the duo unsuccessfully attempted to “network” their way into the factory (Eisfeld is not as connected as Munich or Berlin), Raider sent the unsolicited email and the duo got a reply. They then flew over to Eisfeld to see the factory and try to convince Feintechnik to manufacture blades for their budding company. “[A co-worker] said, ‘You have to care about this. You will make it a success. Please step in.’” Becker recalled. “That is the start of Harry’s.”

Over the next nine months, Feintechnik and Harry’s learned about each other through a traditional supplier-retailer relationship, and then Harry’s pulled together $100 million in funding and purchased the factory. The takeover was anything but hostile. “We dealt with them for nearly a year as customers. They were family. People knew them,” Becker said. “They visited us. And that made a big difference.” On January 21, 2014, the two co-founders stood on palettes to match the height of the six-foot-eight Becker, and together they announced the deal to factory workers in an emotional speech. “It was very touching. I think there were tears in some eyes. There was lots of applause, and that’s not normal if you take over a company,” Becker said. With one move, Harry’s went from being a not-yet-profitable startup to a vertically integrated razor company with nearly 600 employees. All this before their first birthday.

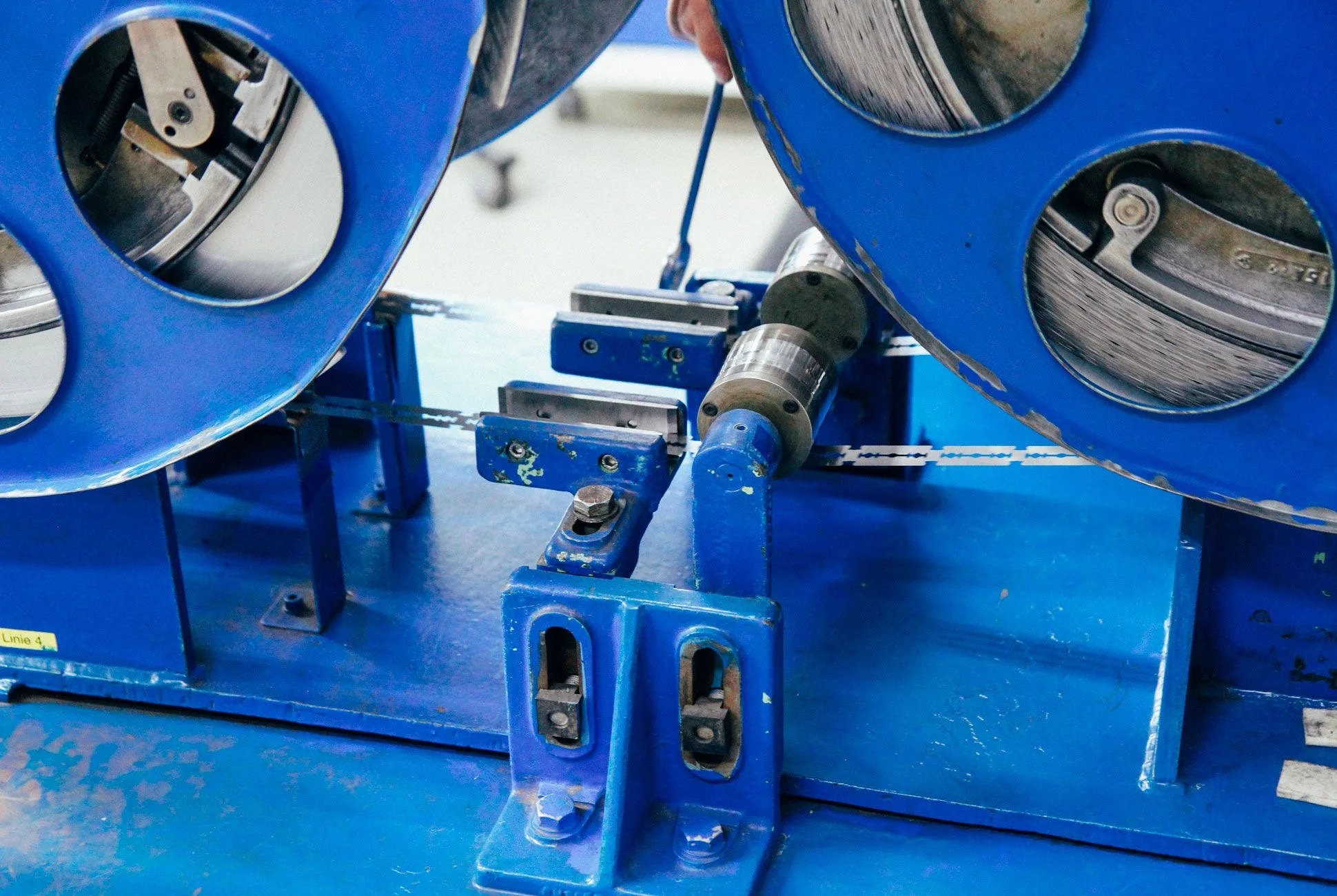

Walking around the factory in late September, it was clear that Feintechnik lends an important air of credibility and authenticity to Harry’s, like a veteran athlete brought into the locker room to mentor the star rookie. The manufacturing process for razors is complicated and nuanced, but Feintechnik has been honing their process for 96 years. They start with two-mile-long rolls of thin steel that are punched to size, then tempered in extreme heat and cold, then ground and coated to sharpness before being finished in multimillion-dollar finishing machines. The factory also has its own secret sauce: a design called the gothic arch, which allows a blade to stay sharper, longer. (Only a handful of other manufacturers, namely Gillette, have managed to produce a gothic arch by machine.) “It’s a miracle of physics and mathematics,” Becker said about the company’s proprietary method of producing the arch. “We changed the company from a grinding company to a mathematical company,” he said. And now, to a startup.