As important as the designers employing eco-friendly materials in their designs are, those that make the raw materials — or treat the raw materials, in the case of Green Matters Natural Dye Company — are vital as well. Transformational change within the fashion industry begins with the textiles — bettering both how we harvest and make them and also treat them, too. Sure, we could all be spending and buying less, choose to focus on slow fashion and thrift whatever else we need, but putting the onus on the consumer alone means no sizable shifts in the way companies operate occur. And fashion will never be more sustainable unless the big brands are on board.

How can we, the consumers, encourage these corporatists and conglomerates to consider the impact overproduction, and all of the excess that comes with it, both at the point of harvest (for materials like cotton) or and through the process of production (for materials like polyester)? We pressure them — by shopping at smaller labels that emphasize sustainability or bigger brands, like Patagonia, that have made pledges to the environment, while making many of these same pledges ourselves. Changing the way we shop changes how the money gets divvied up, and damaging a brand’s bottom line is the quickest way to catch its attention.

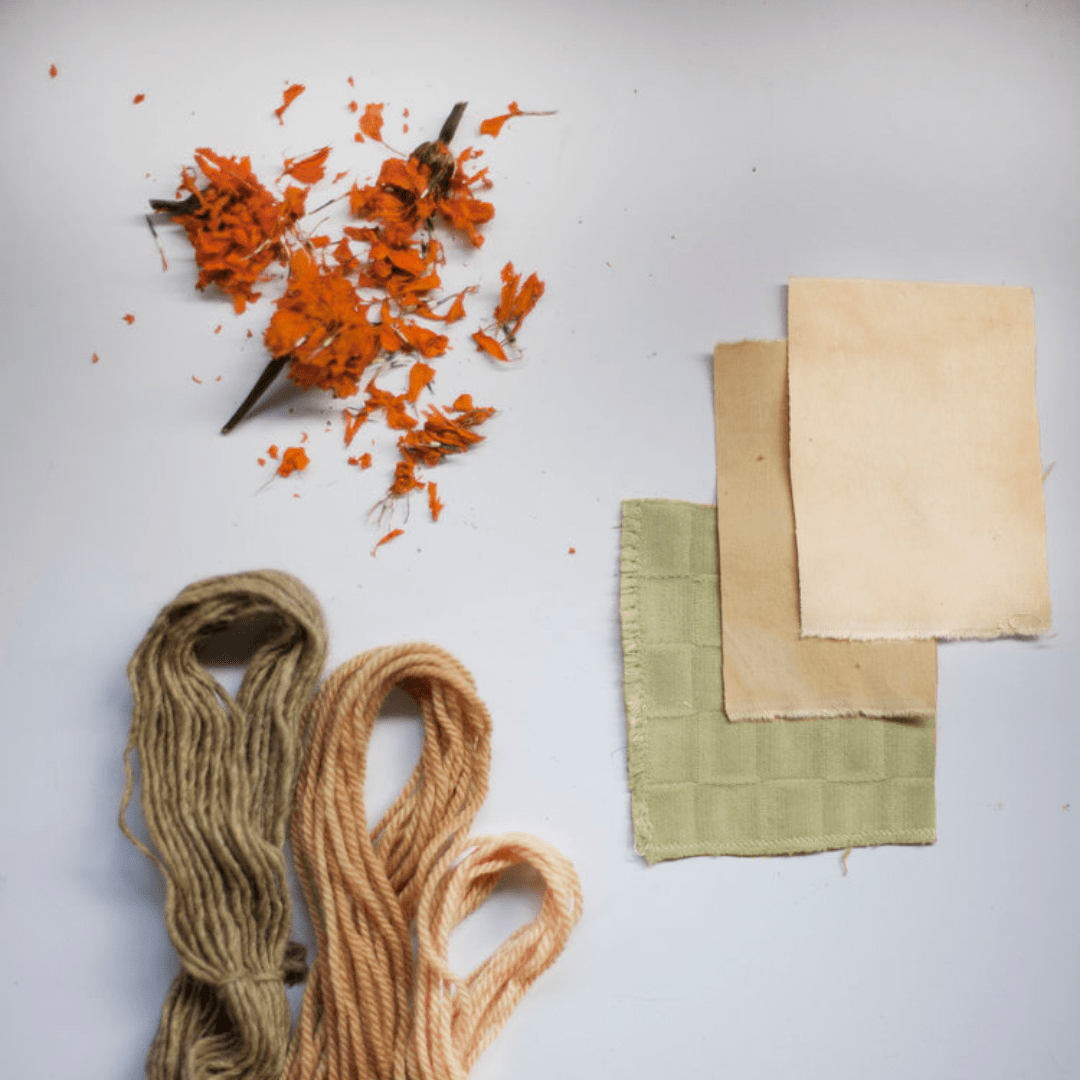

Smaller makers and manufacturers play a pivotal role, too, though. Green Matters Natural Dye Company, a Lancaster, Pennsylvania-based manufacturing facility for plant-based textile dyes, for example, can show what’s possible, and, more specifically, what transitioning to more eco-friendly means of production could look like and entail.

Founder and CEO Winona Quigley, a graduate of Parsons School of Design, where she concentrated on natural dye processes and color development, has worked with Alex Mill, Stitch Fix, Chipotle, 3Sixteen, Ground Cover and a bunch of other brands both big and small — like MoonJuice, Quince, Wol Hide and Araks. Her work, she says, started shortly after graduation — in 2015 — but began in school, where she noticed an opportunity to develop, as she plainly puts it, “a dyeing solution that can meet the manufacturing needs of fashion brands without damaging the environment.”

That may sound simple at the surface level, but successfully doing so, Quigley will tell you, is a tall task. Textile development is the second leading water polluter in the world, largely because of synthetic dyes. To understand how she strives to change that, we spoke with Quigley to break down what exactly natural dye is, what it can be made from and where you might her carefully crafted colors next.

How did Green Matters Natural Dye Company start? What’s your background?

I was in fashion school, and my glamorous view of the fashion world was shaken up a bit by discovering that the fashion industry had an outsized impact on the environment, both with how much pollution was generated in textile dyeing and finishing, as well as the carbon footprint created by manufacturing a garment that needs to be transported to multiple countries to be completed. This sparked my research into natural dyes while I was a student at Parsons the New School for Design, which I focused on for several years. We received a small grant to launch the business, so it felt very natural to jump right into working full time on building Green Matters right after graduation.

What’s it been like to build your business? Do you get a lot of outreach now that your portfolio has grown?

In the first few years, we had to do a lot of work to get our samples in front of brands that we felt aligned with our vision. While my background was in fashion, I had to really quickly learn about sales and be comfortable doing outreach. Now that we have done work for a wider variety of brands, we have more businesses coming to us either through our website or through a recommendation.

This is a broad question, but you ask it on your own site: Why natural dyes? What’s so bad about commercial ones?

Natural dyes are compostable. Synthetic dyes can contain carcinogens and are formulated not to break down while washing. This means they don’t break down once they are dumped into a body of water and start disrupting the aquatic ecosystem by preventing UV from reaching algae. This creates a chain reaction, which eventually impacts the people living in communities downstream.

When you’re not fulfilling orders or dyeing for other brands, what does your typical workday entail? Is it color research? Dye experiments? When you were growing plants and flowers for dye research was it tending to those and planning new crops?

I am really thankful for the team at Green Matters because a lot happens on the average production day. I typically get into the dye house at 6 AM, and start heating up the boiler and filling the machines with the hot water needed for the first scour wash that starts a dye cycle. Our machines — the largest of which holds 800 gallons of water — take a long time to fill, so staying on top of the production schedule is crucial to getting out the door at a reasonable hour.

The team starts coming in between 8:30-9:00 AM. I pass off the dye machine schedule to one of our production team members while briefing the sample dyer on the projects that have come in. During the day, I am bouncing between the production team and my desk to keep things running smoothly, while taking video meetings with clients and potential clients, generating quotes for potential new clients, making sure we have the inventory we need for everything we are working on.

Any research is typically done at sample scale by our sample dyer. I always say her job is the most fun. There are some tasks that I don’t have the heart to ask anyone else but myself to do, like composting avocado pits. After cooking these down for dye, they are very mushy, wet and don’t smell the best. I shovel these out of the kettle we cook them in, into bins that I load into a golf cart and dump in a large compost pile on the farm we are located on. A good day wraps up around 6 PM, while I finish off the dye cycle after everyone leaves.

You have evidence of a much more holistic assortment of colors on your site. How long does it take to expand the wheel, per se? Do you know immediately what colors a flower or plant material will produce?

Our dye offerings took years of development, and are still evolving. Some of this research was done because we started the company, while I was still a student. I worked on natural dye research for about two years, and some of those dyes we use today. We have some dyes that we eliminated from our service as they were either hard to source, or did not perform as well as another dye that could create a similar color.

When working with a new material, we have stopped trying to expect what color it will create. Often people will expect a plant to produce a dye color that is similar to the color of the plant — i.e. avocado is green but the pits produce a pink dye.

What has it been like working with brands like 3Sixteen, Ground Cover or Quince? Are they coming to you with colors in mind or is there a degree of collaboration? Do they always understand the process?

The experience we have working with certain brands is highly dictated by the type of result the brand is looking for. 3sixteen and Ground Cover both have creative teams that are really excited about the natural process and are easily guided by the natural color outcomes, so it is very collaborative and open minded.

Sometimes we work with brands who need more education about the natural dye process, which is something that we have gotten really comfortable with. This often means setting expectations with designers who are more familiar with synthetic dye houses who are able to color match with precision. I think the best client relationship starts with our team making sure to share as much information as possible about our process, which helps potential clients identify if our service is a good fit for them.

What does natural dye going “mainstream” look like to you? Is there a formidable way for everyone to transition to natural dyes? Can it be scaled?

I think that both the buyer’s expectations and how we approach natural dye will need to change in order to scale in a meaningful way. In order to offer natural dye to mass market, plants would have to be sourced in a thoughtful way to ensure plants were being farmed sustainability — i.e. not degrading soil, not using plots that could otherwise feed people, etc. This might mean seasonally available color palettes (something the fashion industry already offers, just for different reasons) or tapping into more waste streams for dye (like avocado pits).

For the consumer, natural dyes being more ‘mainstream’ probably means that the person purchasing the clothing is spending more, and purchasing less frequently. Additionally, it means investing in the life cycle of our clothing by properly caring for our garments so they last longer. Changing how one buys and cares for garments is necessary to stop the impact fashion has on the planet, regardless of whether those garments are naturally dyed or not.

While natural dye will never fit into the fast fashion production line, nor should it, it has been really exciting to watch products we have dyed hit larger markets. In the past year, we have done work for Chipotle and Stitch Fix (both publicly traded companies). We have become well versed in setting expectations when working with brands who are used to predictability of synthetic dyes, as well as helping them educate the end user of the product on how to best care for their naturally dyed garments. We see this as a sign that we can continue to scale plant-based dyes, and make this type of fabric finishing available to wider markets.