7 photos

“Typically, the most popular denims in the world are going to be a three-by-one right-hand twill weave, 10 to 12 ounces, red cast (vs. green cast), and — right now — vertical slubs rather than cross hatches,” Scott Morrison said, standing in front of a wall of 70 selvedge denims in his SoHo store, 3×1 Denim. He was not speaking in tongues; he was simply speaking the new language of denim.

Morrison grew up in Rancho Mirage, California, as a golfer, went to University of Washington to play golf on a scholarship, drew up a business plan in college to launch a golf company, then finally moved to New York in 1997 and started in on denim. He came to the party at the right time. “I remember going and buying a pair of Replay Jeans and looking at the inside and going, ‘Holy shit, what is Made in Japan? Japanese Denim? Japanese Wash?’ They were $125, which at the time was $25 more expensive than any other product they were making.” This was an advantageous enlightenment; from the late ’90s — Morrison places it around 1999 — onward, premium denim has been booming. What started with Earl Jean, Frankie B and Paper Denim & Cloth then moved into 7 For All Mankind, JBrand, True Religion. Then the wave really caught on, and leading up to the present premium denim companies have begun ad infinitum.

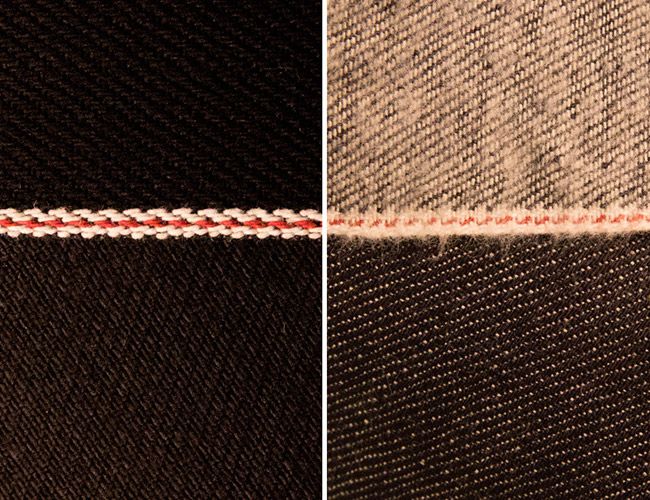

Back in 1999, Morrison and Ken Girard, head of Cone Mills product development, traveled to Japan. Morrison said that at the time, the Cone Mills selvedge shuttle looms in North Carolina were still. Selvedge, or “self-edge” denim (so named for the tightly woven band on the end of sheet of denim), was the classic style of denim — “it’s the record player of denim,” said Morrison — and Cone Mills is one of the founding fathers of the fabric. Starting in 1891, they were a premier fabric manufacturer, and throughout the early and mid-1900s, they made only type of denim: selvedge denim on shuttle looms. But as technology evolved and the economy demanded faster, cheaper denim, the new rapier, projectile and air jet looms took over production. When Morrison and Girard headed to Japan, no one was ordering the slower, more expensive selvedge denim. “At the time, the big brands, Gap, J.Crew, Esprit, Levis, Lee, Wrangler — every one of the American brands were focused on this moderate price point.”

What Morrison and Girard found in Japan were mills focusing on premium denim of the sort North America once made. He remembers it being better across the board, from fabrics to stitching to wash. And it left an impression. “My dogs are named after Japanese denim mills — Kurabo and Nishimbo. I was a bit obsessed, to say the least.” After that trip, Morrison’s travels in Japan (and also in Italy) continued, as did his study of premium denim manufacturing. He believed he wasn’t the only one who’d buy into this domestically born, internationally perfected practice. Morrison’s idea — shared by only a couple other premium denim companies at the time — was to bring this quality back to American jeans. “The premise was, why can’t we do the same thing in the States?” said Morrison.

“I know our customer is this one guy that’ll walk in and be like, ‘That’s fucking awesome, that’s what I want.’”