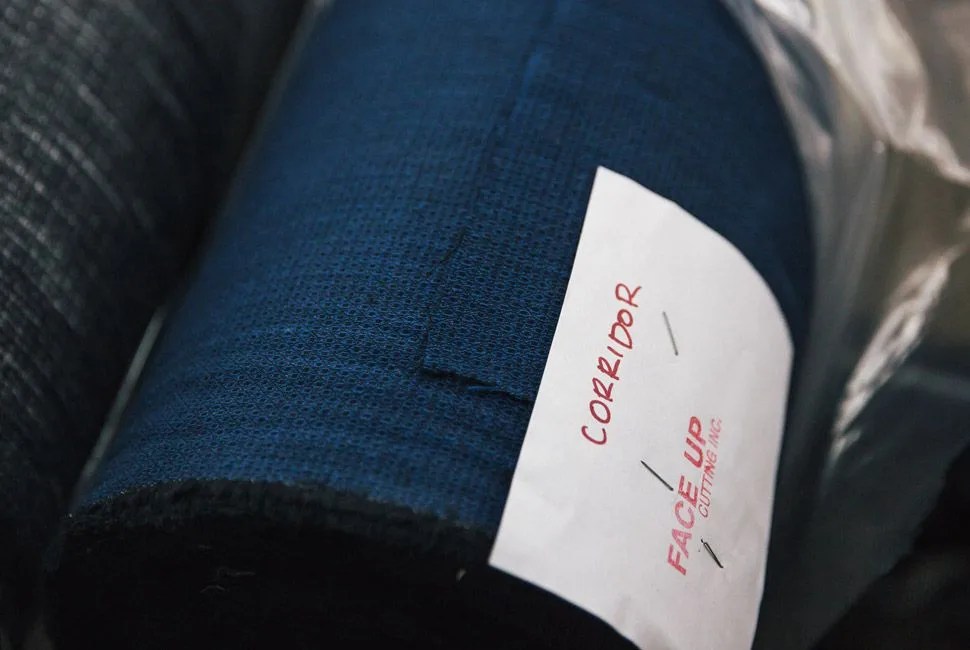

The 16th floor of a building in New York City’s Garment District is where I find Dan Snyder, founder and designer of his burgeoning clothing company, Corridor. We’re in their production factory — a workspace they share with brands like Rag & Bone and Ball and Buck — and space is tight. Huge, cluttered sewing tables occupy most of the floor space, garments hang everywhere from high racks and guarding the aisles are bins of rolled-up textiles. As Snyder leads me to a cutting table in the back, the middle-aged women don’t look up from their sewing machines. There, he pulls out a few rolls of the Italian linens that’ll be used in Corridor’s next line, and tells me to touch them. Soft and patterned intricately with madras, checkers and colorful stripes, these high-quality fabrics are a point of pride and differentiation for Corridor. Ask Snyder, and he’ll say that Corridor is just as committed to making their clothes in New York as well.

“This made-in-New-York thing is really important to me,” says Snyder. “But it’s also important for me to be in New York and be part of the process.” At two years old, Corridor is essentially a startup. His company consists of about 10 employees, seven of whom are sewers, which forces Snyder to be very hands-on in every aspect of the business. In New York he’s able to meet fabric agents, attend fabric shows and purchase small-milled textiles from Italy, other parts of Europe and Japan. It’s an immersive process for Snyder, but it’s one that he’s grown accustomed to.

“People don’t realize that it’s expensive to make good clothing. They look at something from Uniqlo or from Gap, and there’s a reason why it’s so cheap.”

Before starting Corridor in 2013, Snyder had no fashion experience. Right after getting his Masters in International Relations from Tufts University, he had a three-year stint working for the FBI as a contractor. He then briefly worked for the NYPD in their Counterterrorism Division. But his heart was in fashion. While in D.C., Snyder befriended a tailor who in turn inspired him to borrow his aunt’s 1970s Kenmore sewing machine and start taking classes with a bunch of “old Korean ladies”. Soon he was tailoring his own clothes, his friends’ clothes and eventually he started selling original work in pop-up shops. He quit his job and began traveling between Washington D.C. (where his family lived), Boston (where he lived) and New York (where he bought fabrics and sold clothes). He called the space between the three cities his “corridor”, which became the name of his brand.

Coming into the business, Snyder admits, he was a fashion outsider. He never went to fashion school, and the past two years have taught him a lot about the industry — especially when it comes to cost. “People don’t realize that it’s expensive to make good clothing,” he says. “They look at something from Uniqlo or from Gap, and there’s a reason why it’s so cheap.” Most of Corridor shirts run north of $200, a result of buying the best fabrics and constructing each shirt in New York. Asked if he thinks their shirts are overpriced, Snyder replies, “Not at all.”

The central reason behind each shirt’s steep price is the fabric he uses. Snyder buys his textiles from fabric agents in New York who source their materials from mills in Italy and Japan. When choosing a textile, Snyder says he stays away from poplins and flat materials that don’t have any frequency. “I want materials that have texture and idiosyncratic elements.” Corridor’s past lines were made with Japanese cottons, indigos and Italian linens. “We make clothing that’s accessible and interesting, but not heavy handed,” he says. The look of each shirt is also unique. Corridor has a mid-Atlantic, preppy style, with many of their shirts adopting vibrant floral, nautical and checkered patterns. When asked what inspires him, the first thing Snyder says: New York City. “In New York, fashion is everywhere.”