Ducks and geese have been around for centuries and, as you may have noticed, haven’t changed much. Which means that when it comes to down insulation, the only way to innovate is not with the material itself, but with how you place it into a garment.

This new approach is different, thanks to strategic tucks and darts in the fabric that allow the down to move in three dimensions, enabling each individual baffle to go with the flow, minimizing cold spots and maximizing insulation.

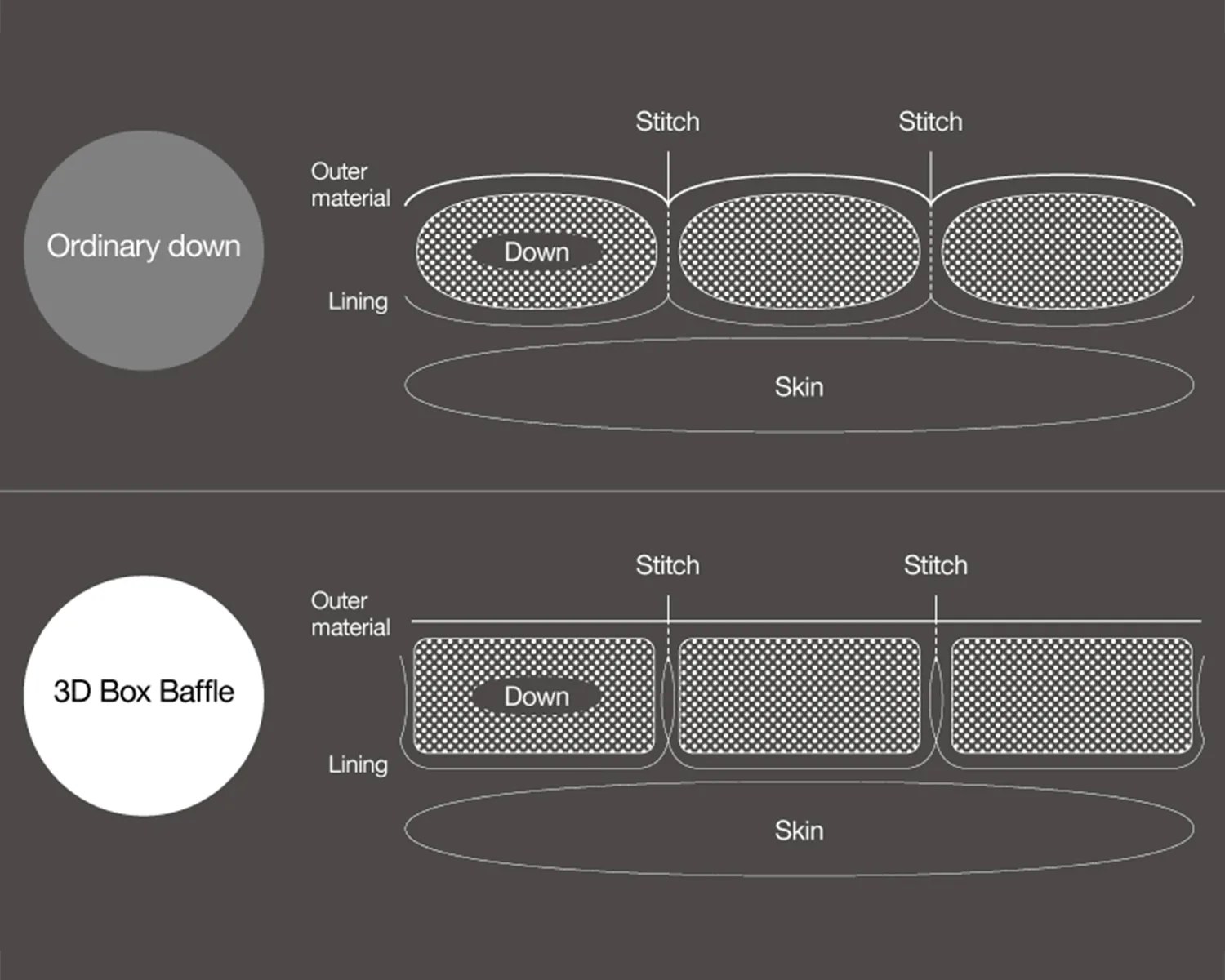

The main way to do so is to tinker with the baffles, the compartments that prevent the down from moving around or clumping up. With its latest, ahem, baffling move, Japan-based Goldwin has hit upon a potentially game-changing formula. It’s called the 3D Box Baffle, and it’s poised to make all previous insulation tech obsolete.

Goldwin

GoldwinAnother dimension

The biggest weakness with traditional baffles is that even within all those little boxes, the actual down can move and compress in response to the body’s movements.

That’s where this new approach is different, thanks to strategic tucks and darts in the fabric that allows the down to move in three dimensions, enabling each individual baffle to go with the flow, minimizing cold spots and maximizing insulation. Not unlike the design itself, the advancement’s effect, Goldwin says, is three-fold.