13 photos

Walking into Thule’s U.S. Headquarters in Seymour, CT, it’s obvious that this is an outdoor company. There’s a bike room to store the road and mountain rigs of Thule employees who commute. Just outside the building a few guys are drenched in sweat, holding mountain bikes and knocking on the door — looks like they’ve forgotten their key cards. It turns out it’s the president of Thule U.S. and a few other senior executives back from a hard lunch break ride on Thule’s on-campus single track. Sweaty handshakes exchanged, they promise me their lockout wasn’t a little bit of pre-tour theater, and the quick interaction makes one thing clear: Thule isn’t just a company making outdoor products; it’s a company of outdoor people making products to best serve their peers, and they’re not messing around.

MORE BEHIND-THE-SCENES COVERAGE Aboard Lufthansa’s Boeing 747-8 | Visiting the Highland Park Distillery | Photo Essay: Timecrafters

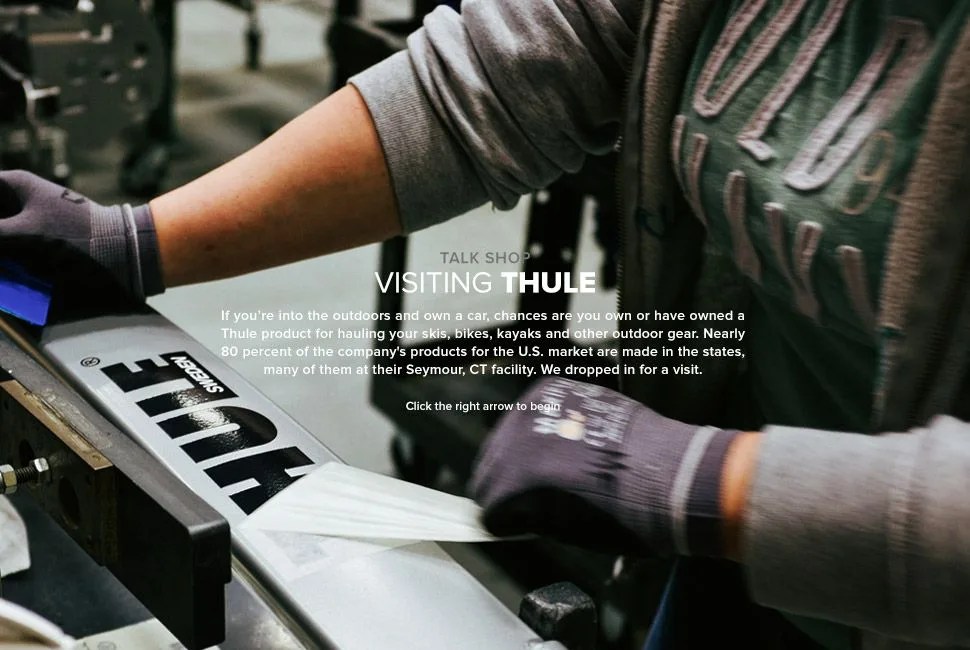

If you’re into the outdoors and own a car, chances are you own or have owned a Thule product for hauling your skis, bikes, kayaks and other outdoor gear. A Swedish company, Thule was founded in 1942 by Erik Thulin, and his first product was metal grills to save headlights (they used to be made of glass) from being shattered by rocks. In 1962, Thule released their first roof-mounted rack, for skis, and have been modifying and adding to the system since then. Thule’s presence in the U.S. market took an important turn in the 1970s, when the gas crisis led to car design that included fewer universal rails in favor of aerodynamics and gas mileage. This small change proved pivotal for Thule: now every car might need unique mounting hardware. Recognizing this opportunity, as well as differences in sporting interests between the U.S. and Europe, Thule decided to set up a headquarters in Seymour, CT.

From the start, Thule U.S. was given a large amount of autonomy from its Swedish parents. This has resulted in a Swedish company that takes great pride in being American made. Of the products Thule sells in the U.S. market, nearly 80 percent are made in the States, much of them in the Seymour factory or in facilities in Pennsylvania and Chicago. U.S. product development and testing are also carried out almost exclusively here in Seymour.

The factory floor at Thule doesn’t feel like factories of yore. There’s a lot of light and it’s very clean. People are smiling and laughing as they assemble a variety of rack systems. Each assembly station is set up with an eye toward ergonomics, with mats on the floor and tools suspended from overhanging arms to minimize repetitive picking up and putting down motions. Each assembly station is completely flexible and can be used to assemble whichever Thule product is in the highest demand. Had a light winter in the Northeast and ski racks aren’t selling? No problem. Switch to bike racks.

The factory floor at Thule doesn’t feel like factories of yore. There’s a lot of light and it’s very clean.