Do a blind taste test of an Impossible Burger and a Big Mac and you probably won’t be able to tell them apart. They both taste, feel, and look like beef – and that’s far from coincidence. Impossible Foods uses fermentation to replicate every quality of meat down to the juice that squirts out as you bite, camouflaging the soybeans you’re digesting. Many biomanufacturing companies see this model as the path forward.

“Performance needs to come before impact,” says Matthias Foessel, CEO of Beyond Surface Technologies. “A lot of companies get this wrong. If our fabrics don’t perform we won’t stay alive as a business, let alone succeed in reducing the industry’s carbon footprint. It’s the only business model that works.”

“Performance needs to come before impact. If our fabrics don’t perform we won’t stay alive as a business, let alone succeed in reducing the industry’s carbon footprint.” —Matthias Foessel, CEO, Beyond Surface Technologies

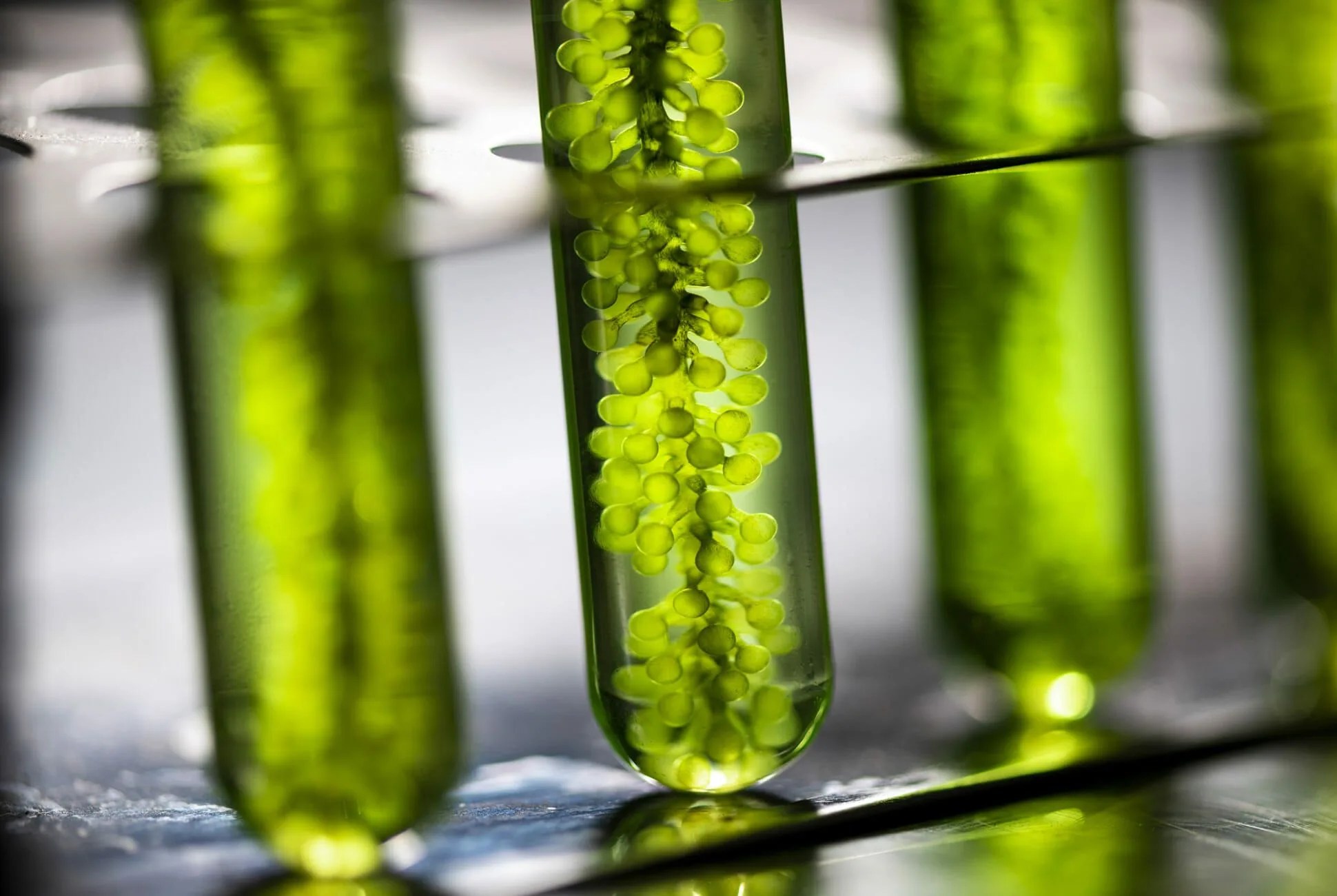

After more than three decades in the textile industry, Foessel is qualified to speak in such candid terms. Beyond Surface Technologies (Beyond ST for short), a Swiss lab with a staff of 10 full-time scientists, is a world leader in green chemistry, creating textile chemicals from plant seeds and more recently, microalgae.

Unlike sustainable fabrics of a decade ago, the lab’s products are engineered to outperform their crude oil peers. Brand partners include Patagonia, Adidas, Levi’s, The North Face and Lululemon, and last year Beyond ST supplied fabric for upwards of 150 million garments, from soccer jerseys to outdoor baselayers.

Growing microalgae in fermentation tanks is a very sustainable process, with lower greenhouse gas emissions and water consumption than oils produced from other sources. Microalgae grown in fermentation tanks efficiently convert sugar into renewable, low-emission oils and materials that go into consumer products.

The process also cuts the ugly parts of manufacturing, like heavy metal extraction and long, carbon-expensive supply chains. This reduces costs while simultaneously reducing the environmetnal impact of the products — and it revolves around tiny organisms like microalgae.