Northfield, like many towns in Vermont, is small. Even the valley it sits in, an impression carved out over centuries by the Dog River, is small, at least in comparison to the more-famous Mad River Valley, which routes its way through the Green Mountains seven miles to the west. The population of Northfield is just over 6,200. And yet, Northfield is somewhat famous. Famous for the local military university situated at the southern end of town, and for its five covered bridges (there are 100 or so in the state), but perhaps more so now for the product that comes out of the mill at the end of Whetstone Drive.

That mill is called Cabot Hosiery, and its product is the Darn Tough sock, the toughest sock in the world. Darn Tough has been in business since 2004, when Ric Cabot, a third generation sock producer, found himself perched on top of the trap door of bankruptcy with a mill, 35 employees and a small army of sock knitting machines. In the two decades that preceded that moment, Cabot Hosiery had been a private label manufacturer producing socks for Gap, Banana Republic and a host of other big name brands.

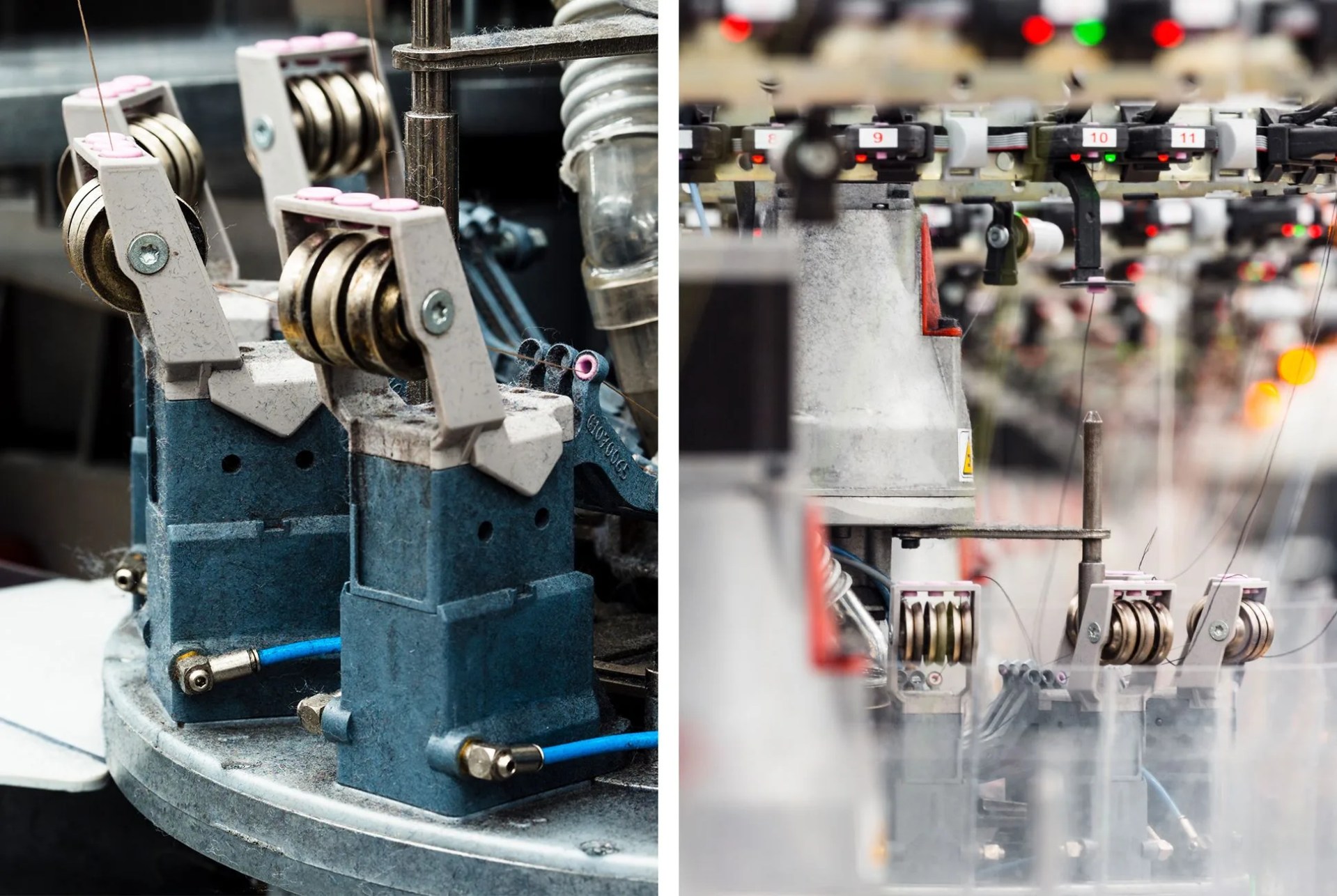

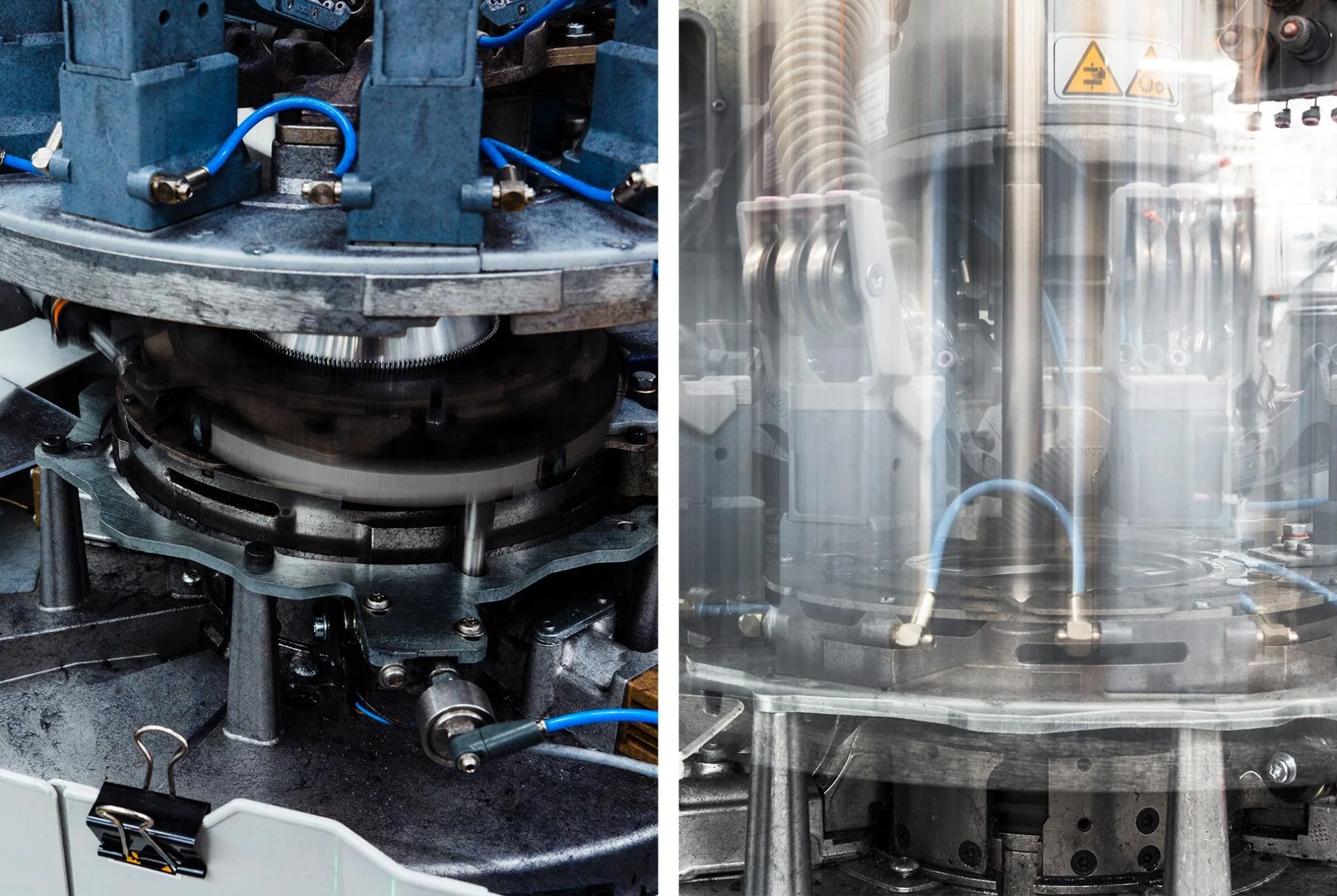

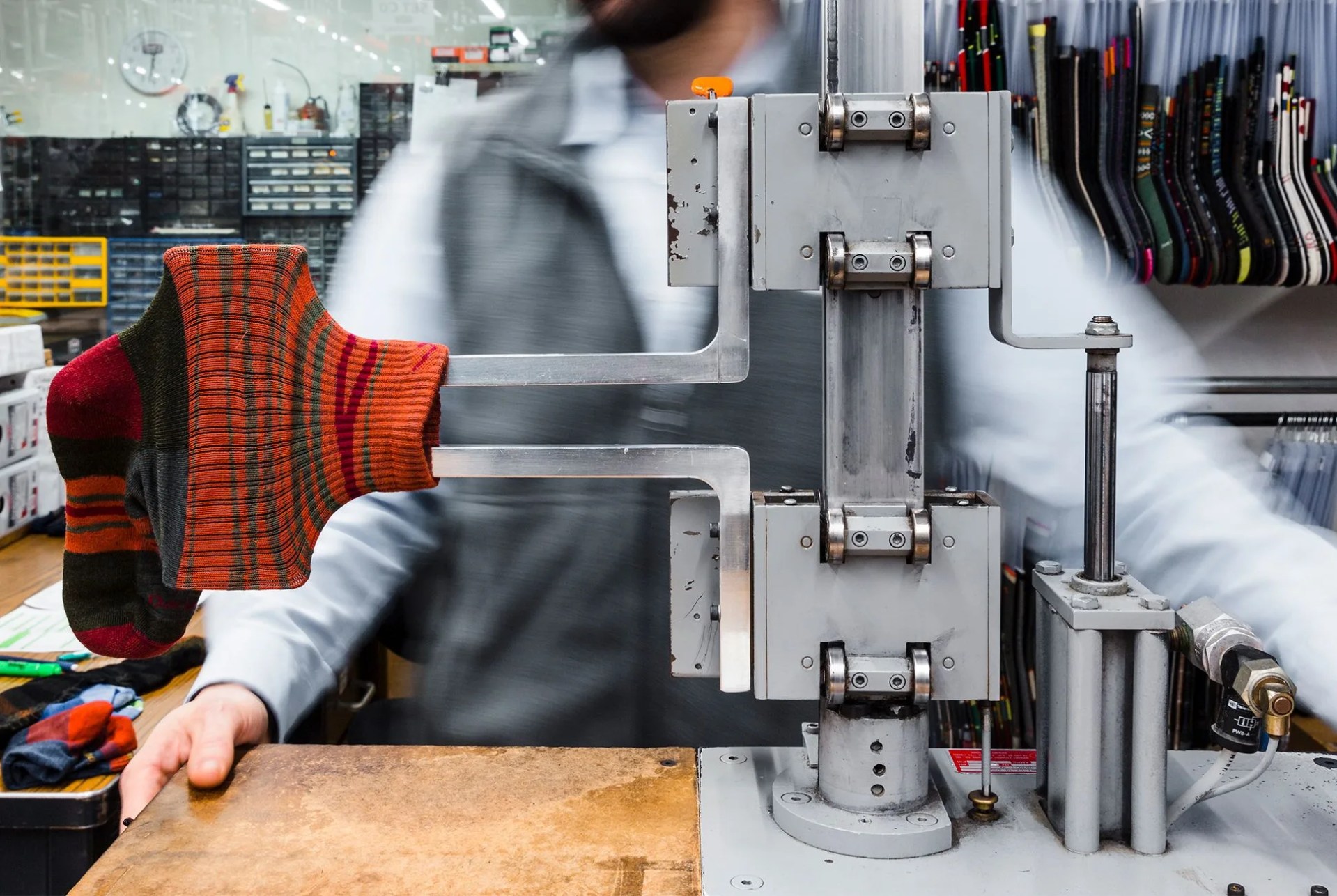

“As opposed to giving up, I tried to figure out a way to keep it going,” says Cabot. “I figured with my three generations of sock making know-how and experience” — Cabot’s father and grandfather were also in the business — “and our own factory, a workforce, the equipment and the beginnings of a raw materials library, if I couldn’t make the best sock out there then no one should be able to,” he says. So he and a colleague named Harvey Stabene took apart one of the Italian-made knitting machines, modified it, and put it back together. Then they knit a sock.

“…if I couldn’t make the best sock out there then no one should be able to,” says Cabot.

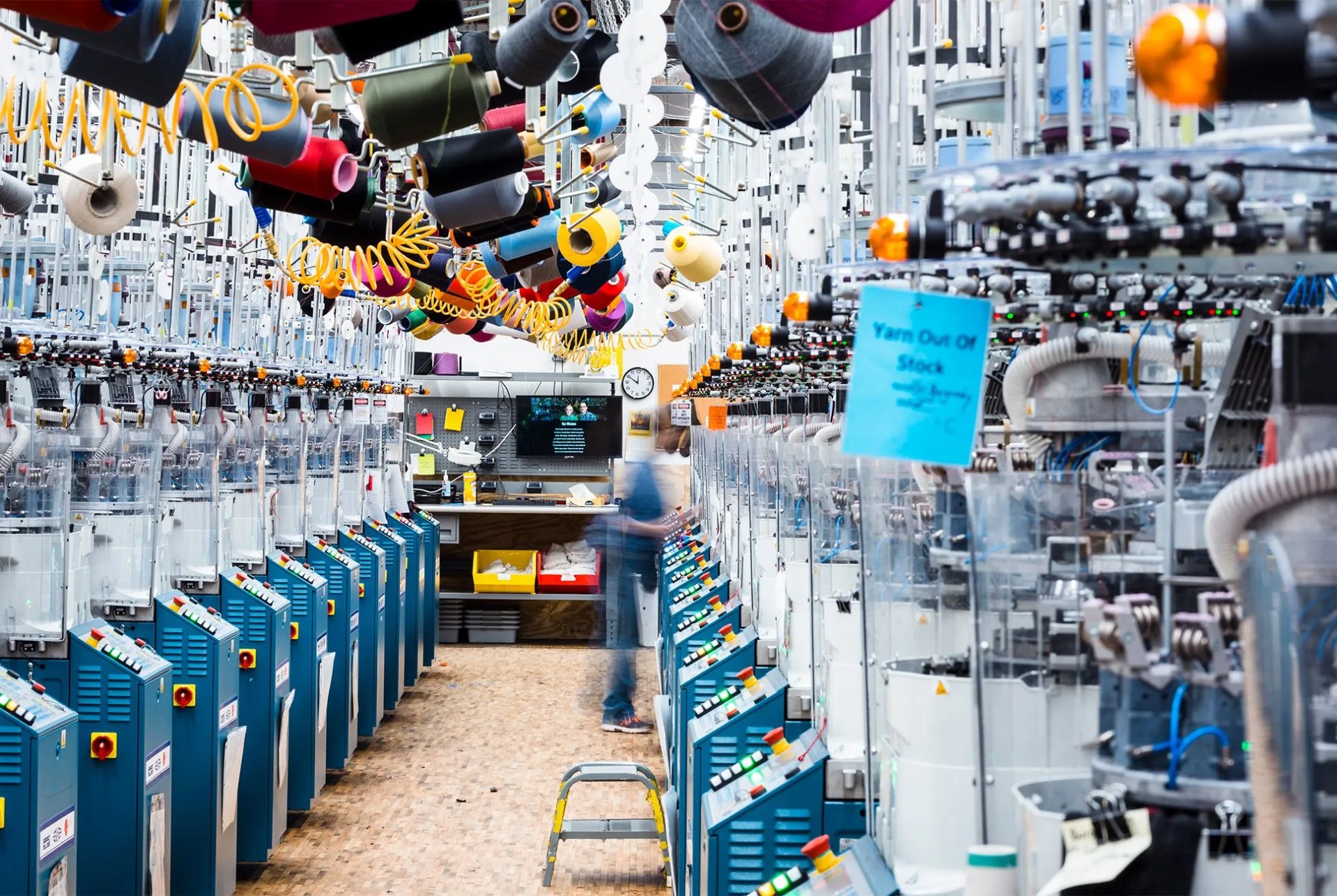

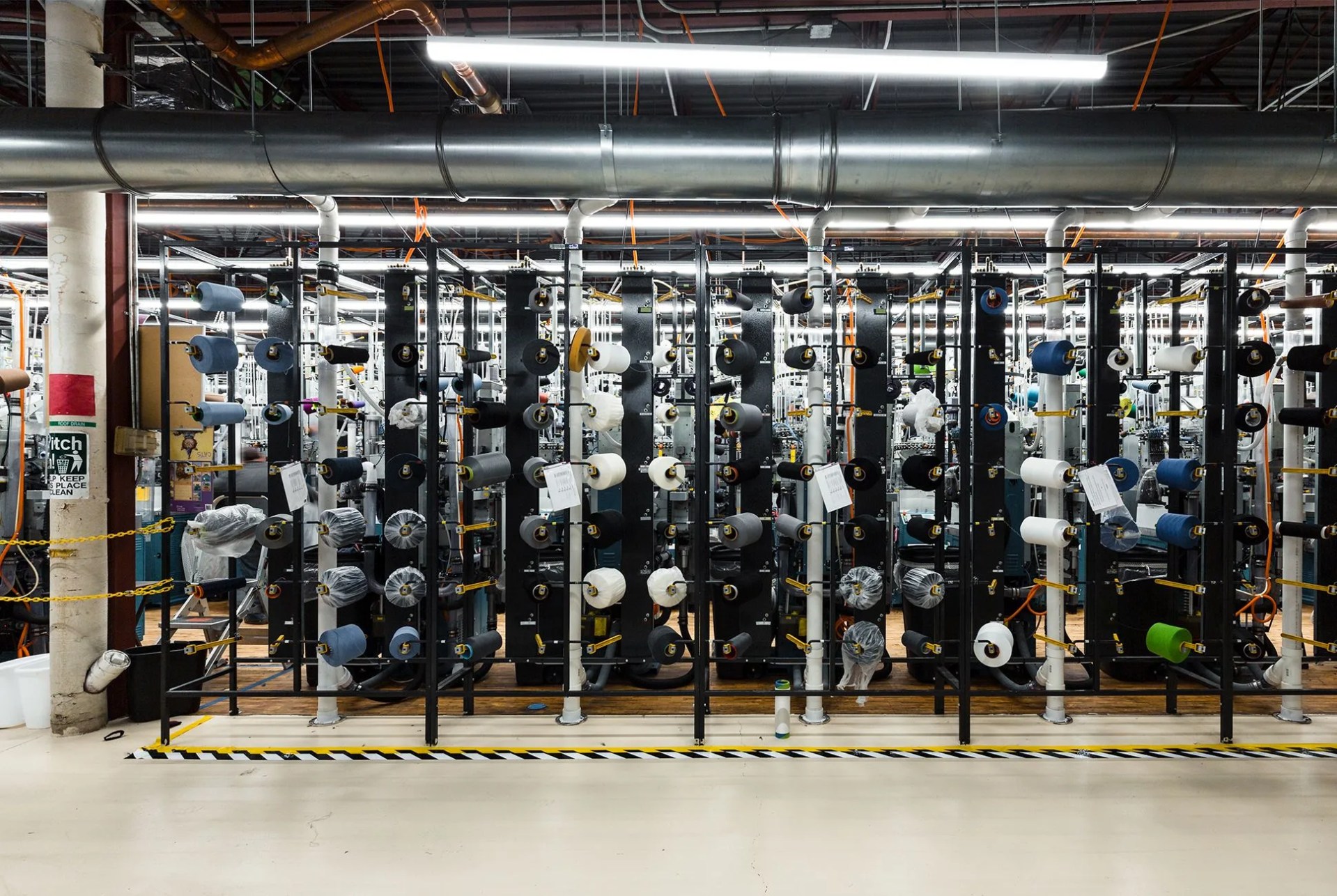

Since that time, Darn Tough has grown into a business worth over $40 million. Now, the mill at Cabot Hosiery contains 208 of those modified machines, and they’re running 24 hours per day, five days a week. They collectively knit thousands of socks per day, and it takes 250 employees to keep the mill running at full steam.

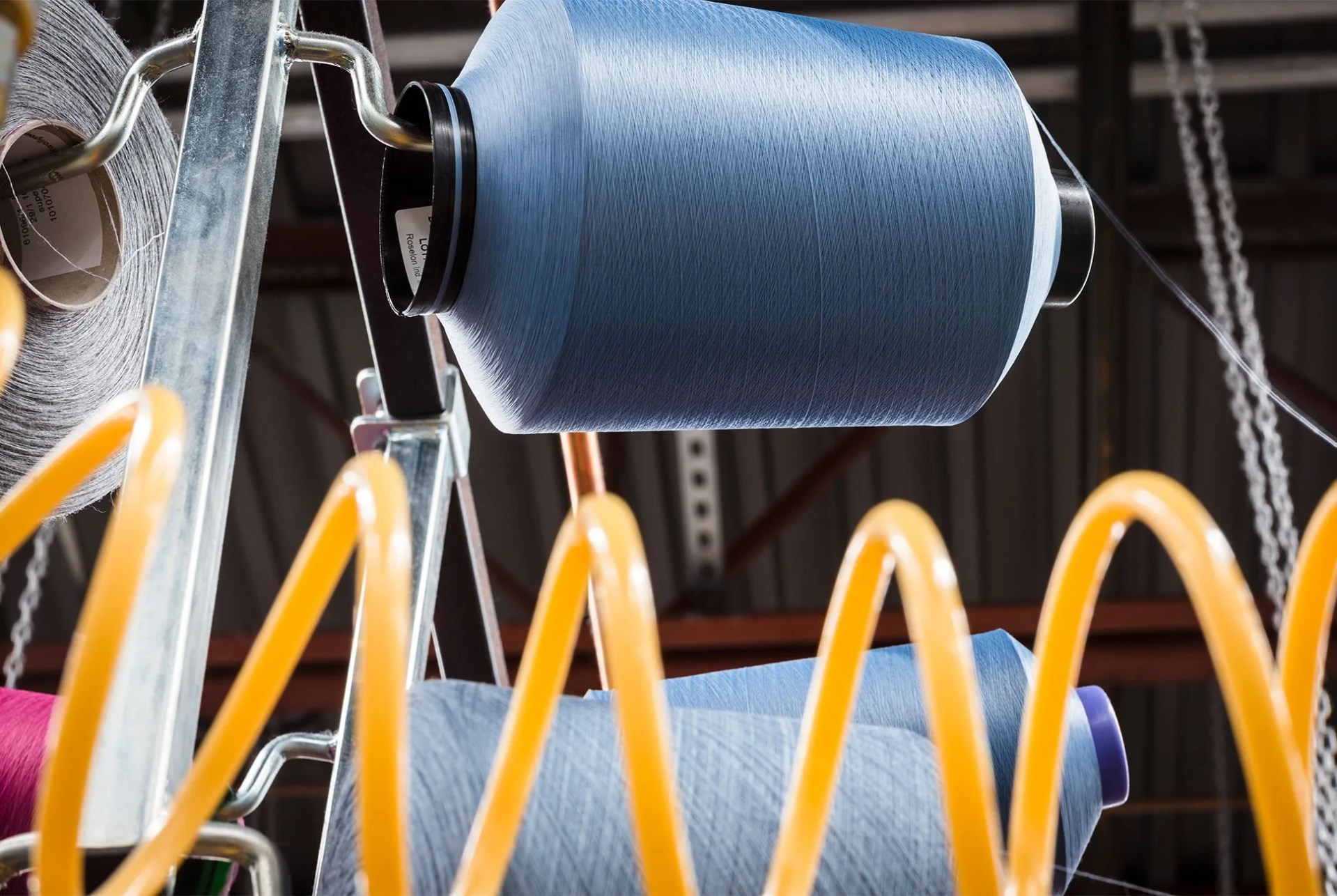

The foyer of the mill is spartan. There’s a check-in desk with a bulletin board and hallways leading to sets of offices. It’s normal, quiet, but head through a set of doors and the ambient volume ticks up two notches. Take a left through another set of doors and enter the vast space where the knitting happens, and it jumps to 11. The scene inside is Willy Wonka meets mass industry; a world simultaneously dominated by harsh chrome and vivid color. The ground is filled with boxy knitting machines; the air above a tangle of bright yarn, furiously spinning to depletion as the needles perform their work.

The record of Darn Tough’s growth can be traced on the knitting room’s floor; as the company expanded it purchased more machines and knocked down walls to add new rows of them — called sets — to the fleet. During the process, new flooring was added, but not to match. Last year, the company grew by over 40 percent.