Sometimes, it takes a dream and a chance to deliver innovation and invention. In the spirit of pushing the boundaries, Osprey — one of the leading packs brands in the outdoors market — has just released its most tech-forward pack to date, two years in the making: the Osprey UNLTD.

According to Osprey founder Mike Pfotenhauer as revealed in a video released by the brand, UNLTD is an acronym that stands for “unlimited,” with the pack representing “our pursuit of new processes, design concepts and technologies, with less regard for costs involved.”

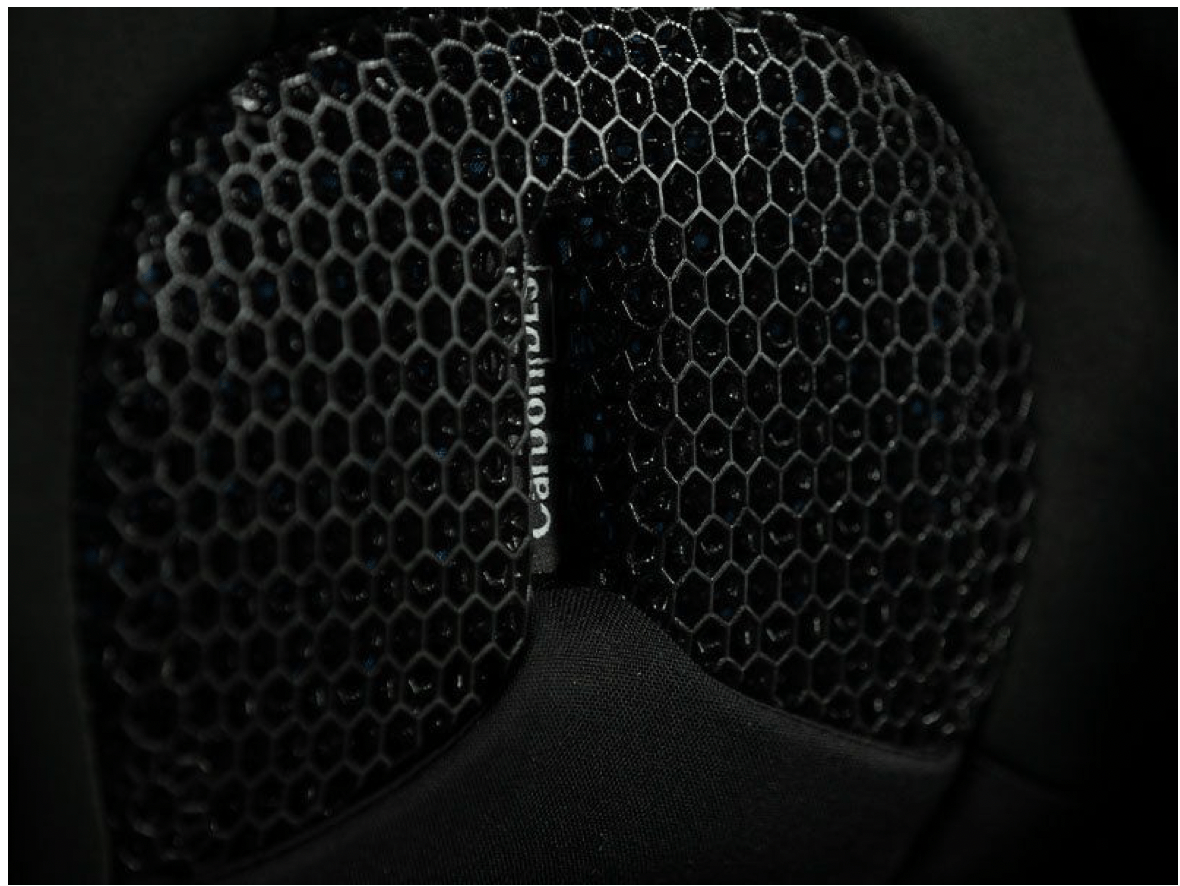

With UNLTD, progress was the pursuit, and cost took a backseat to creation. The UNLTD pack makes use of what no pack manufacturer has before: Carbon DLS 3D carbon printing technology. In the fitness category, Adidas uses Carbon DLS in sneakers and Specialized in its saddles, but Osprey is the first to develop a pack that utilizes the forward-thinking tech.

The UNLTD features 3D-Printed Fitscape Lumbar support, which uses Carbon DLS to provide superior ventilation, mapped cushion support, and an anti-slip surface that keeps your pack in place. In the frame, aluminum alloys combined with stainless steel high carbon and injection molded hubs create a stronger framework, which allowed Osprey to create a back panel that can handle a greater load than traditional models.

Along with the carbon lumbar support, Osprey’s team also developed new, high tenacity fabric weaves, a double rip 210D lightweight main fabric featuring ultra-high molecular weight polyurethane. Pfotenhauer says, “This is a fiber that is super strong and tear resistant, and we have developed a grid work in our fabrics to make the strongest fabric yet that we’ve used.” The UNLTD includes a rain cover made from the same premium material, as well as