I meet Freezer Fred about halfway through a tour of outdoor retailer REI’s research and development lab, located at the company’s Kent, Washington headquarters. I’m immediately spooked, a reaction that becomes even more pronounced — and visceral — the moment I touch him.

Fred is a wired-up, pulsating 155-pound mannequin with a Frankensteinian vibe, wrapped snugly in a down sleeping bag and set within a coffin-like deep freezer. He has one job: to lie there and steadily radiate heat equal to that of a living human body. He has an artificial heart — a pump, actually — that circulates 15 gallons’ worth of warm water throughout his rubbery torso and legs to maintain a steady internal temperature of 98.6 degrees Fahrenheit.

His keeper, engineer Greg Dean, the senior manager of innovation and testing at REI Private Brands, describes Fred’s role with a disappointing lack of ghoulish delight: “We’re able to test the insulative qualities of down sleeping bags with him,” he notes, as I struggle to take my eyes off Fred. “If the temperature inside the freezer rises by a certain amount, we know the bag isn’t retaining the heat. You can touch him if you want.”

I hesitate — I’m not sure why, exactly — then reach in and place my hand on Fred’s shoulder. I’m startled by the sensation, the shock of recognition. Fred feels exactly as warm as a human body, which is patently obvious, but that becomes patently creepy when you consider how often in your life you touch something that looks sort of human but isn’t remotely alive — yet is precisely the temperature of an actual living person, which it’s not. Once I’m over the freaky novelty of the experience, I mull the missed opportunities Fred represents for REI — a fantastically weird kind of new body pillow, say, or maybe a car warmer for cold winter mornings. He at least deserves his own Instagram.

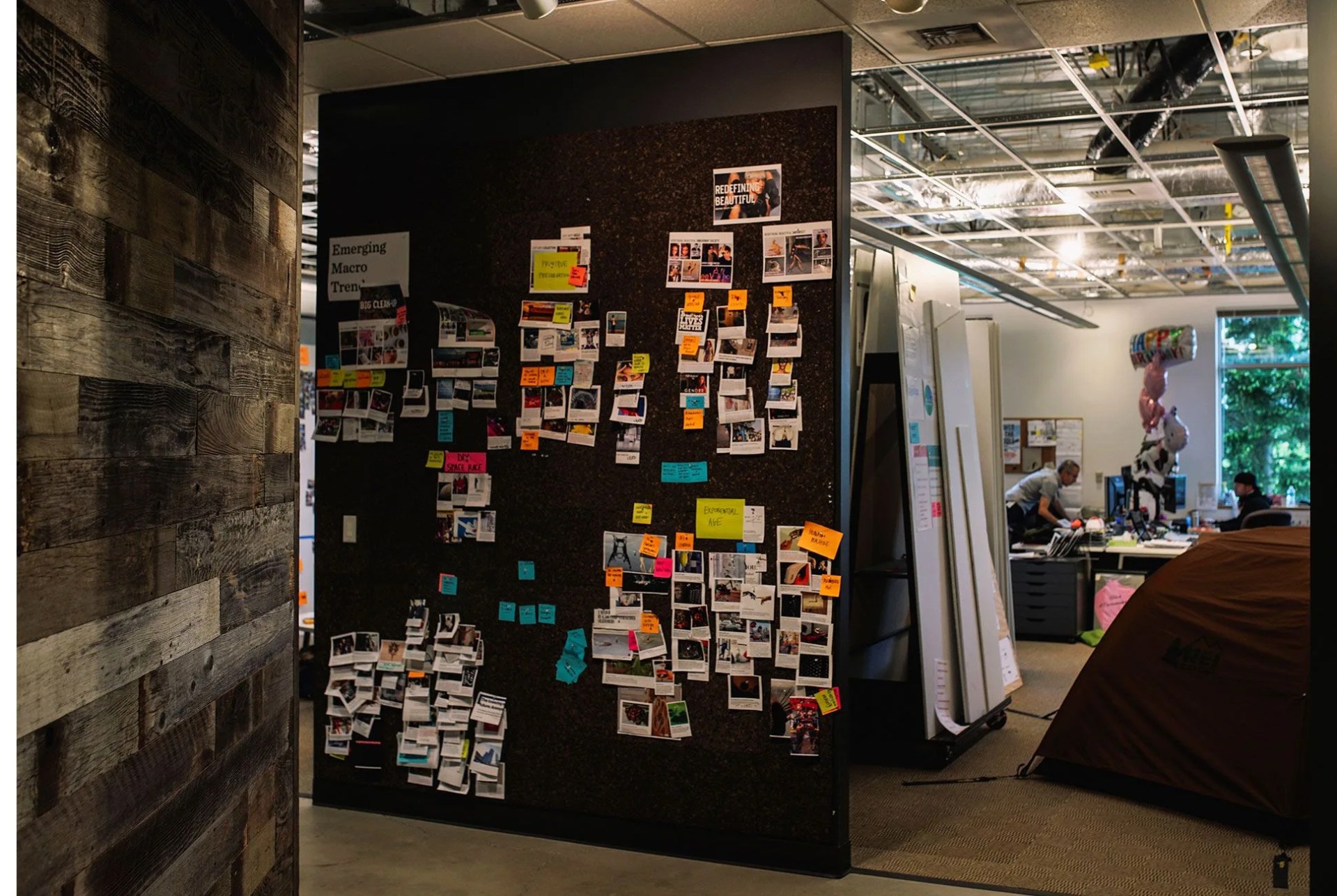

But Fred’s handlers are already pretty busy these days, given the overall energy in the lab, which is nicknamed “the Foundry” within REI. Though the 80-year-old company has produced its own products throughout most of its history — in addition to selling apparel, sleeping bags, climbing gear, boots, bikes and backpacks from other top-shelf manufacturers — it’s been pushing aggressively of late to fully tap its pronounced expertise in outdoor gear though its own in-house branded products. They’re now as innovative, durable, and smartly designed as anything else sold by REI.

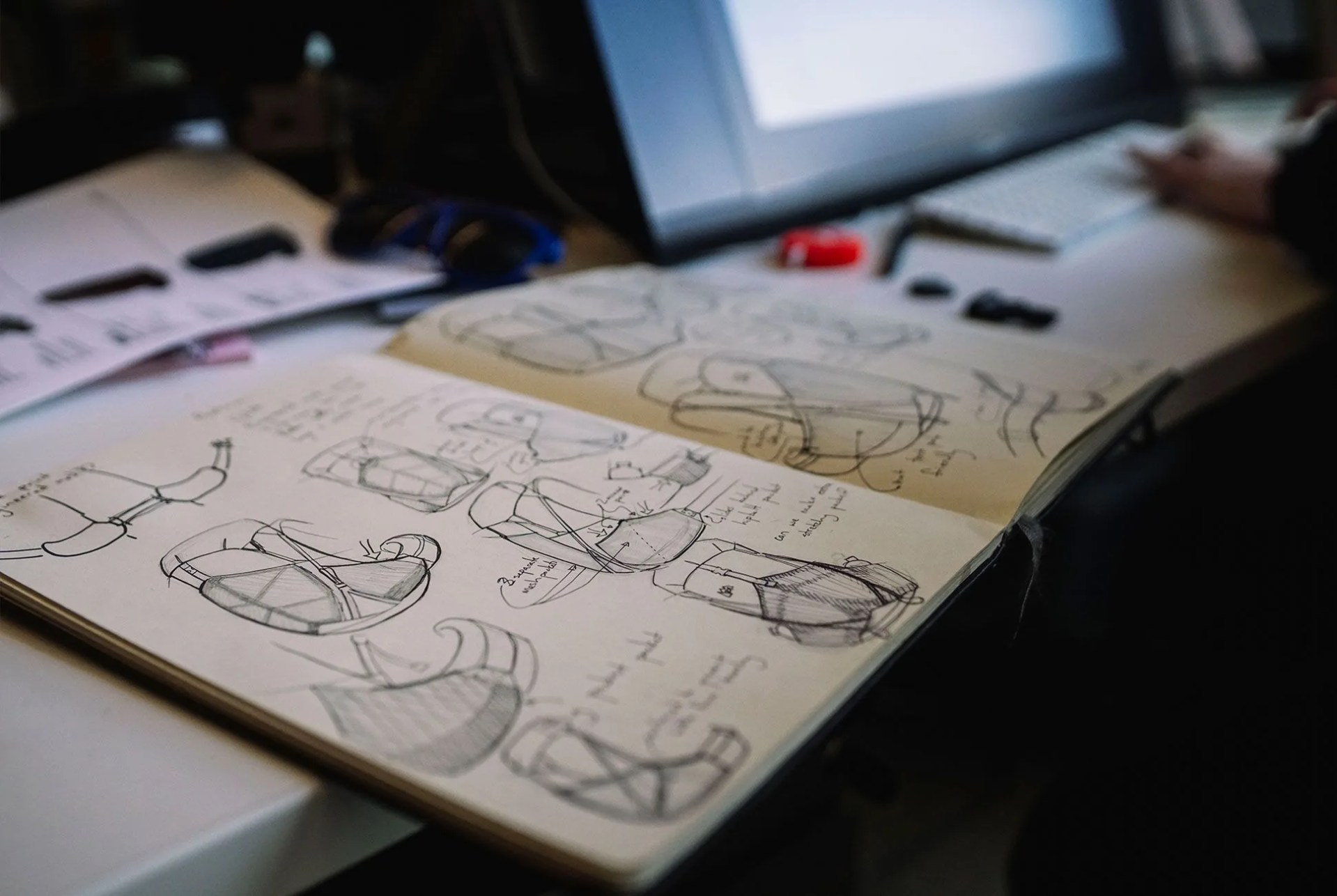

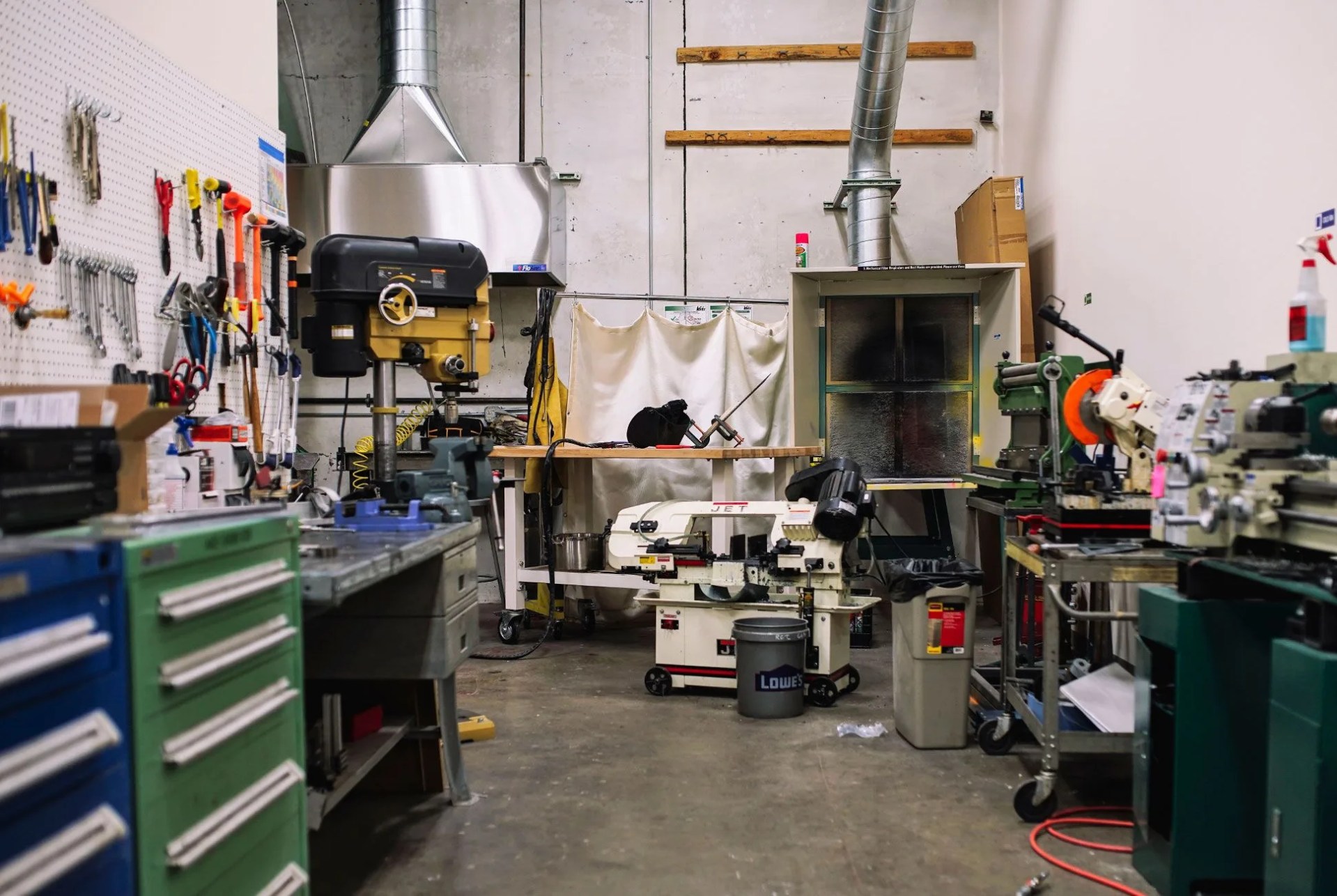

In the Foundry, ideas for new products are born, developed, tested, honed and then advanced into production. The rapid-prototyping process they deploy involves everything from 3-D printing and computer-aided design, to evaluation and feedback from REI members, to customized testing via Freezer Fred and dozens of other technologies. The system allows the engineers to quickly develop product samples without having to commission the work from manufacturing partners overseas, which can result in a sluggish pace. Products that are closer to reality are tested and evaluated in third-party laboratories around the world, using equipment more elaborate than Freezer Fred, but what goes on in Kent simply helps REI move R&D forward far more briskly, via solid preliminary feedback and early-stage validation. REI gave us a behind-the-scenes tour of the Foundry for a glimpse into this process.