First-hand experience has taught us that Nike Golf cranks out some top-notch golf equipment. Despite the crew here possessing a wide range of handicaps and skill levels, Nike clubs and balls have won universal acclaim amongst the Gear Patrol crew. Still, one wonders what’s behind the ascendancy of one of golf’s fastest growing brands. That’s why, when Nike Golf invited us to check out their state-of-the-art research and development facility in Ft. Worth, Texas, we jumped at the chance to peer behind the curtain.

Home to Nike’s club design gurus and tour service staff, the joint is affectionately called The Oven – the place where big ideas and design innovation are cooked up fresh. Our visit left us impressed with Nike’s commitment to advancing the science of the game, as well as with the experienced craftsmen that are behind the brand’s rise. Hit the jump to read more.

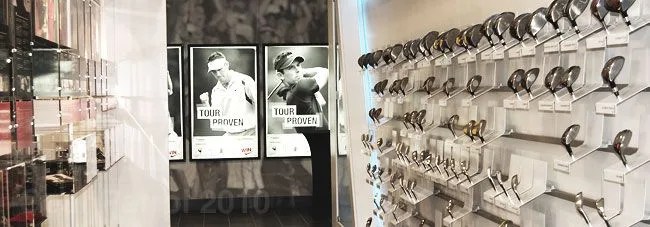

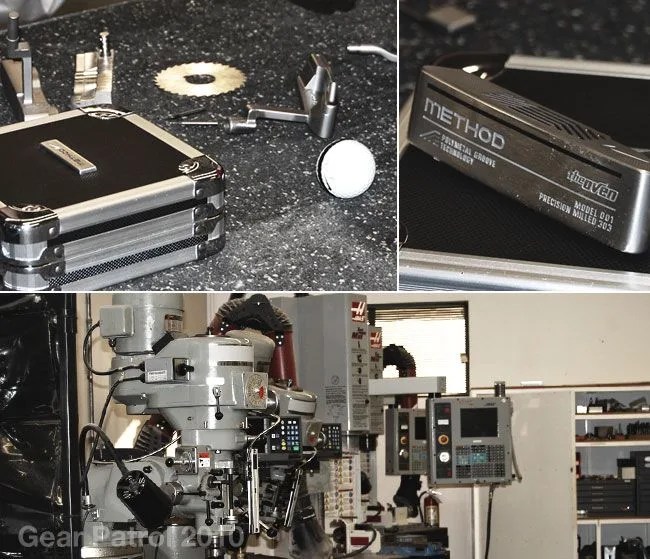

Simply put, for the techno-geek golfer (read: us), The Oven is a metal and machinery-filled wonderland. Originally established in 2002, the facility has undergone several major expansions in its eight years, the sum total of which have left Nike’s club wizards with nearly 50,000 square feet of ball-cannoning, CAD-rendering, precision-grinding, robotic-testing, PGA-pro-consulting playland workspace. Stepping outside, one finds an immaculate 129,000 square foot short game area featuring both synthetic and natural grass greens, as well as bunkers, practice holes and a scenic water feature (which doubles a practices area for shoeless, pants-rolled-up shots). Here Nike engineers and athletes can consult on a variety of short iron and ball testing issues in real-world conditions. That means that guys like Anthony Kim, Justin Leonard, and Tiger himself prowl the grounds on a regular basis.

The Nike Oven is a metal and machinery-filled wonderland…

The week that we visited The Oven, the PGA Tour was also in town for the Crowne Plaza Invitational at Colonial. Thanks to Nike, we had the chance to walk the course on the tournament’s first day, seeing many of their tour athletes in action. What’s interesting, though, is that many of those same PGA pros spent their hours away from the course at The Oven having their clubs tweaked, providing Nike with their feedback on up-and-coming designs, and just talking golf and equipment with Nike’s staff. If you don’t think that the best players in the world love to geek out on equipment, think again.