I was in the back room bagging up some breakfast blend when I heard shouting from the café. At that same moment, I smelled smoke and knew that my batch of Sumatran had caught on fire. I dashed to the roaster, flicked off the gas burners and closed the vent. I knew the routine. This had happened before. The cloth and rubber belt had broken, the drum stopped rotating and the beans ignited inside, fanned by the air being sucked in through the vents. Now my hope was that the flames didn’t make it into the chimney and light up the chaff that had no doubt built up inside. If that happened, we’d have to evacuate the café and call the fire department.

Despite the long hours, sweaty work and low pay, roasting coffee remains, to this day, the coolest job I’ve ever had. I moved to Minneapolis in 1991 to finish my English degree. One thing led to another and my four-year degree stretched into seven years, due in no small part to my contentment with my day job. What started out as a part-time barista gig making overpriced lattes for 9-to-5ers became a full-time roasting job, and that diploma didn’t seem that important. Never mind that I went home stinking of stale smoke, with grease and coffee grounds under my fingernails, and couldn’t sleep due to the countless sample cups I’d had during the day. Coffee roasters were the Top Gun fighter jocks of the café culture, and I’d reached the top of the pyramid.

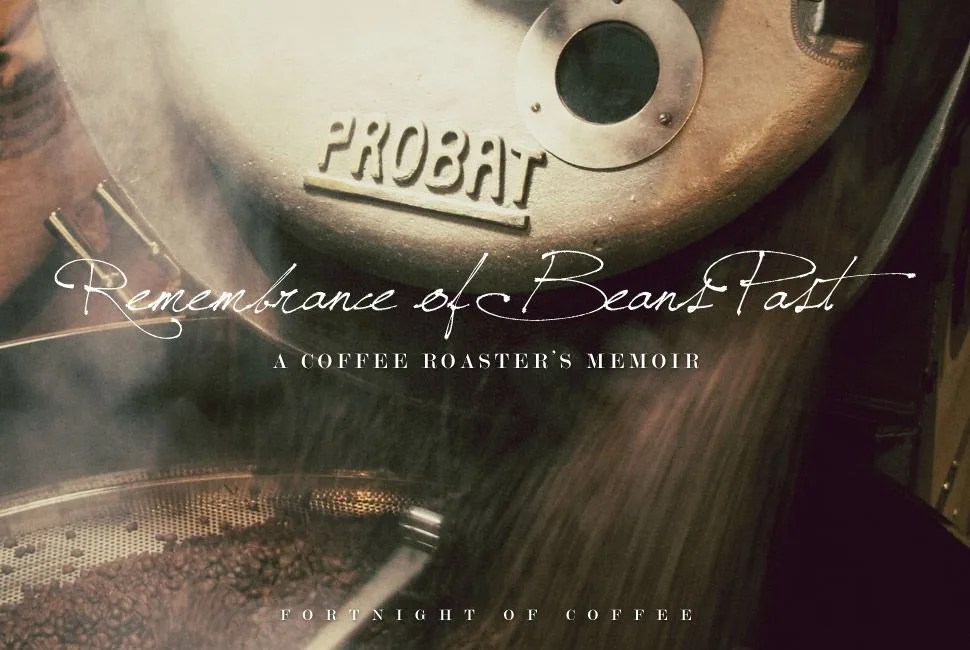

The end of a roast is dramatic. The front door is opened, the cooling tray arms start spinning and the steaming heap of hot, crackling beans comes spilling out into the tray, smelling like Heaven.

One point of clarification: a coffee roaster is both a man and a machine. So while I lent the human element, the real star of the show at the café where I worked was the 1957 Probat LG12. The Probat was a German-made temperamental warhorse that looked its age, sitting in the corner of the café surrounded by 50-kilogram burlap sacks of green coffee. Its matte-black high-temperature paint was peeling and cracking, and knobs and handles had been improvised over the years, giving it a rather battle-worn aesthetic. But while newer roasters had electronic ignition, digital displays and decorative exteriors, in capable hands, the old Probat still produced the most sublime roasts thanks to its seasoned drum and highly adjustable flame rail.

Most gas-fired, direct flame roasters bear a family resemblance. A funnel-shaped hopper on top holds the green coffee and feeds down into the rotating perforated drum inside, which keeps the coffee dancing over the rail of gas flames below. A heavy half-moon shaped front door opens to release the roasted beans into a perforated cooling tray that has spinning arms that keep the coffee moving as it cools. Below all of this is a chaff collector that accumulates the outer “skin” of the beans. The overall appearance is one of a science experiment or undersized locomotive.