The boxing glove is one of those timeless fitness silhouettes, one that’s remained relatively unchanged throughout history. Sure, advancements in materials have helped improved safety, performance and durability over the years — but the way those materials come together in the final profile has been relatively kept intact since the end of the 1890s.

While there’s plenty to be said and admired when it comes to this historical design, that doesn’t mean there’s no room for innovation. Hayabusa, the brand responsible for some of the category’s best boxing gloves, looks to prove that with its latest T3D profile, by utilizing a manufacturing process that screams futuristic — 3D printing. Relying on resin and codes rather than natural materials and handcrafted designs, these all-new boxing gloves weigh in as one of the sport’s most forward-thinking innovations in recent memory.

“This will fundamentally change the industry’s perception of hand protection and comfort,” says Hayabusa CEO Ken Clement. “Hayabusa’s patent-pending design took years of research, development and testing to perfect, and we’re ready to define the next era of performance.”

Hayabusa

HayabusaWhat Does “3D-Printed Boxing Glove” Mean?

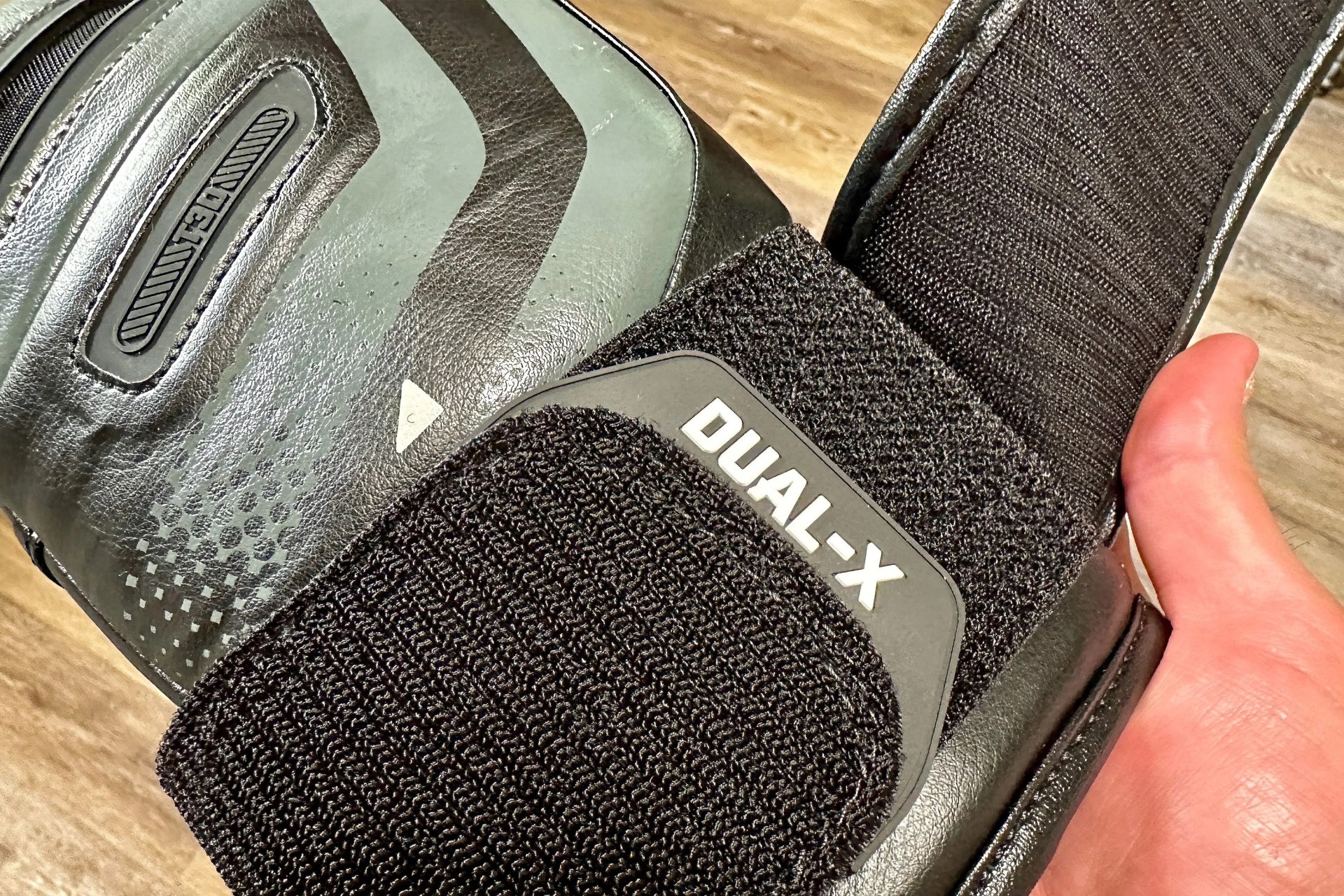

While the notion of a 3D-printed boxing glove could conjure up images of Westworld–like prints over athlete’s individual hands, the root of the innovation lies at the heart of the T3D silhouette — or rather, its padding. According to Hayabusa, the all-new glove profile replaces its traditional layered foams over the knuckles and hand with a complex matrix of resin lattice.

This network of geometric cells is coded to absorb and channel energy upon impact, made possible by thousands of force-damping struts. This makeup, in theory, should be able to outperform and outlast more traditional padding materials like foam and horse hair.