Air. Fuel. Spark. Take one away from your car and you’re going nowhere fast. Increase one, air for example, and things get interesting. More air equals more power — the very principle behind forced induction. By compressing intake air prior to feeding it into the combustion chamber, forced induction squeezes more air in, along with a correspondingly greater amount of fuel. This results in bigger booms. Bigger booms equal faster, more powerful rotations at the crankshaft. In terms of horsepower and torque this is a good thing: forced induction engines will always up the ante over their naturally aspirated equivalents.

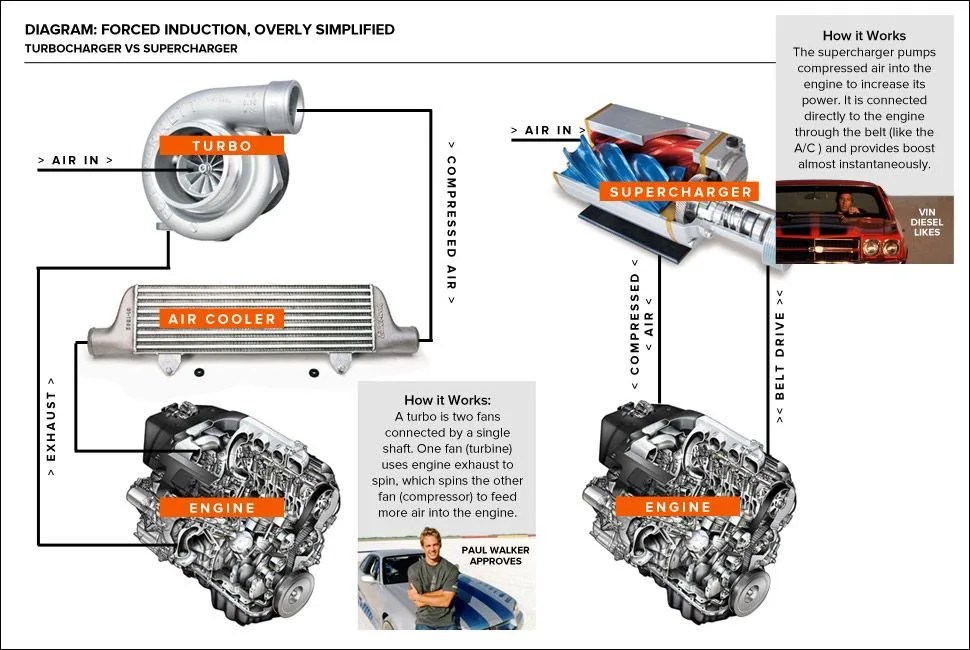

Two systems, supercharging and turbocharging, make this all happen. They differ chiefly in how they generate boost: where a turbocharger is spun by exhaust gases, a supercharger is powered by a pulley via the crankshaft. But before we examine their differences, discuss why they aren’t used everywhere and try to figure out if one is better than the other, let’s take a look at some boosting basics that apply to both systems.

MORE TALES FROM THE TARMAC: The 50 Most Iconic Cars in History | Four-Wheel-Drive vs. All-Wheel-Drive | The 50 Most Iconic Bikes in Motorcycling History

Boost Basics

Boost describes the amount of pressure that a forced induction system creates. A typical system found in that new whip you’ve been eyeballing typically creates around six to eight pounds per square inch (psi) of extra pressure. Compared to a naturally aspirated engine, that boosted beast sucks in almost 50% more air. For the reasons we mentioned above (namely, bigger booms) this enables smaller displacement engines to punch above their weight class, with 4-cylinder engines making horsepower usually reserved for 6 and 8 cylinder blocks, while hitting smashing EPA targets in the process. Sadly, there are some limitations.

The problem lies in the air-to-fuel ratio (AFR) that a motor can handle. An optimum AFR would provide just enough air to burn all of the available fuel. This completely efficient combustion is called a stoichiometric mixture, or stoich, and has an AFR of 13:1 — thirteen parts air to one part fuel. But stoichiometric mixtures burn extremely “hot” and can damage engine internals when the hammer’s down. Under high load, engines cycle at faster RPMs (revolutions per minute) and simply can’t dissipate the extra heat. This creates knock, or pre-detonation, which causes compression levels within the cylinder that are too high. To keep it together, engine management software causes engines to run on the rich side to keep cooler (cylinder) heads. In a forced induction engine similar solutions are applied to cool those bigger booms and soothe scorching cylinder walls. It’s also why your force-fed whip pines for premium at the pumps.

DOUBLE YOUR PLEASURE, DOUBLE YOUR FUN