13 photos

There’s no denying that modern technology has changed the car shopping process for the better. It’s never been easier to compose the car of your dreams via an online configurator, seeing each option come together in a virtual build, and send the specs off to a dealer for an order.

But convenient as it is, it’s cold and impersonal. Like online shopping, it lacks that enriching, deeply-personal element of the experience. Bespoke design is a journey — and the end result is a testament to both the choices you made along the way, and the guidance of the skillful craftsperson that brought your creation to life. And perhaps no automotive customization experience epitomizes that journey quite like the process found in Crewe, England, at the headquarters of Bentley — which is where I went to design a custom Bentley Continental GT.

9 photos

Meeting The Crewe Crew

The automotive luxury market has never been more saturated. With competition offering opulence from all sides, Bentley manages to stay above the rest by emphasizing authenticity.

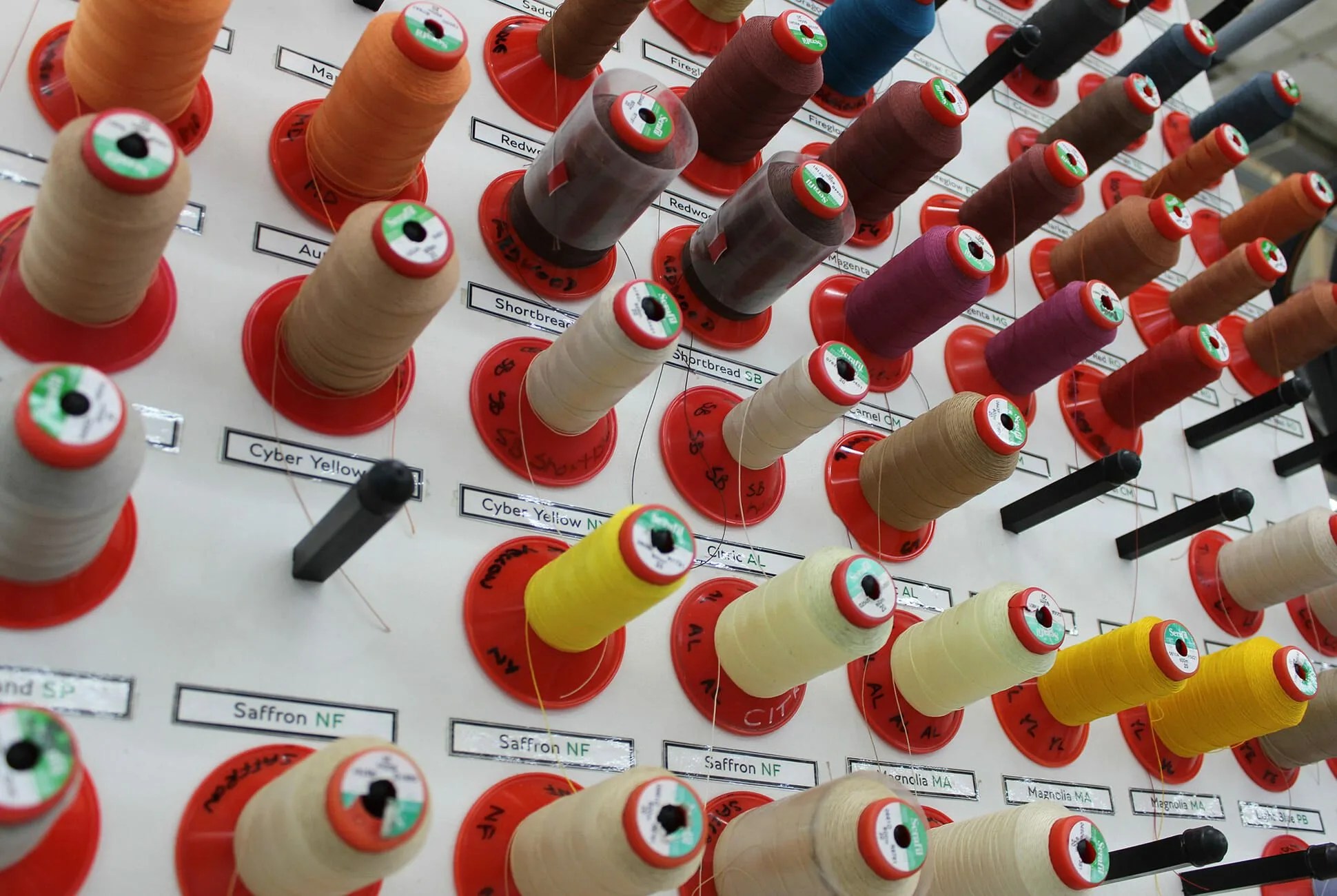

Those in the market for a Bentley will certainly be spoiled for choice when it comes to configuring their own car, but for those who are more discerning, Bentley offers the Mulliner experience, which opens up an entirely new catalogue of options. These go beyond simply expanding the palette of exterior colors; they also add custom hides, wood veneers and other materials unique to Mulliner customers. If even that is too limiting, the ability to commission custom colors is always on the table.