Sometimes, we get so used to a certain product that no true changes are ever really made for years, decades even. Toilet paper comes to mind. Another is the pneumatic tire. Sure, the modern tire is a wealth of technology and high grade materials such as synthetic rubber, sulfur, carbon, steel, etc. Heck, recent years have even given us the run-flat tire, but the vast majority of cars don’t have these kind of shoes. Nevertheless, one requirement has always been the use of air, and if you’ve had your fair share of flats and blowouts over the years, you know how disconcerting your tires’ dependency on air truly is. Well, while you’ve been going about your day and no less, drooling away the night hours unconscious, tire engineers have been working hard at developing the airless or non-pneumatic tire.

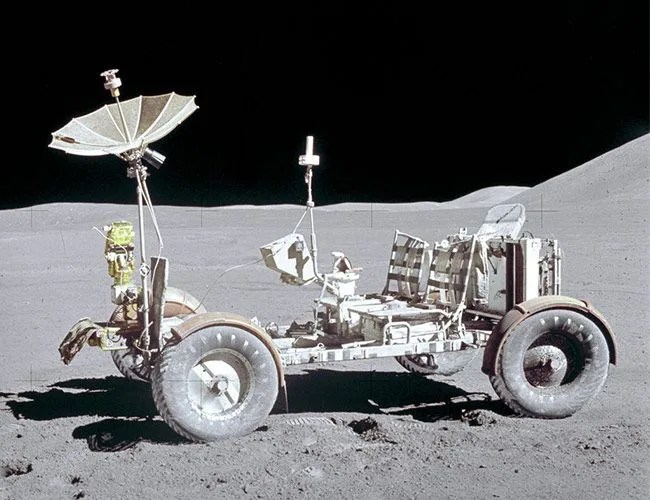

Use of the non-pneumatic tire began in the 1970s for NASA on their Apollo Lunar Roving Vehicle. The Rover’s wheels were made with a spun aluminum hub and revolutionary airless tires made of woven steel strands coated with zinc. The traction requirements on the moon were obviously far greater given the atmosphere and terrain, so the contact area was partially coated with titanium chevrons. Needless to say, this kind of technology for earthbound applications would be unnecessary and prohibitively expensive (essentially, several dollars more than your entire ride).

Then, French tire company, Michelin, started their own development for the airless tire for passenger vehicles in 2005. Awkwardly dubbed the “Tweel”, this airless tire and wheel combination proved quite difficult to develop. The properties of a pneumatic tire enable adjustments in handling (lateral stability), ride quality (shock absorption) and noise reduction. The complete absence of pressurized air affects all three aspects. The Tweel was made of a thin synthetic rubber tread on the exterior, wrapped around a composite plastic band in order to provide road compliance and supporting and shock absorbing spokes made of polyurethane. The spokes, themselves, could then be manufactured at varying thicknesses in order to tweak the Tweel’s handling capabilities and the quality of the ride, from ultra firm to highly compliant. Finally, a rigid aluminum hub was used at the center, where the Tweel would be attached to the vehicle.

The Tweel’s construction setup allowed for solid structural support in place of air, along with significantly increased tread life, up to three times longer than a standard tire. Another huge benefit of the airless tire is the low cost of replacement since only the rubber tread needs to be replaced, rather than the entire tire/wheel structure. The first vehicles to demonstrate the new technology were an Audi A4 and a Segway Personal Transportation vehicle (blowouts on a Segway, a huge concern), though it was rumored that Michelin was planning first issuing their Tweel for military and construction use.