14 photos

Drive past a suburban neighborhood still being developed and, most likely, you’ll see bare house frames made of wood. In fact, I’d be willing to bet that when those houses are eventually completed and furnished, they’ll be filled with wood-framed couches, wooden tables and chairs, bookcases and countless more home decor expected to last a lifetime thanks to that one fundamental material. We have used timber as structural support and design for centuries because the fibrous resource is incredibly pliable, yet sturdy and strong. It’s soft to the touch but has no problem providing a solid foundation, which, if taken care of, will continue to do so for generations. That’s precisely Morgan Motor Company‘s philosophy: an undying dedication to building car frames with Ashwood.

To say Morgan Motor Company hasn’t strayed far from its roots would be too much an understatement even for your average Englishman. Henry Frederick Stanley Morgan worked at and owned an automotive service garage in Malvern, Worcestershire, England (the same town in which the current factory is located). Morgan lived in Herefordshire, the next town over, and needed a cheap and easy way to get back and forth. In 1909, he put his engineering and automotive background to use and built himself a one-off three-wheel car. But what started off as his simple, one-of-a-kind-personal commuter car turned into a handful of examples for friends and family — then, neighbors and strangers requesting three-wheelers of their own.

Morgan’s Three-Wheeler, was affordable to build, own and operate, making it something of a unicorn back at the turn of the 20th century. The average car puttering around the UK in 1909 was incredibly expensive to buy and ridiculously complicated to operate, so few people knew how to run them. Only the wealthy could realistically afford the lifestyle, often with personal drivers. The Morgan Three-Wheeler brought motorized transportation to the people in England — what we’d label today as ‘disrupting the industry.’

“For us it’s the best way we know how to build a sports car, and it’s what our customers want. They want a car built by hand, with traditional methods and not by robots.”

The Three-Wheeler stayed in production until the 1950s, when, James Gilbert, Morgan Motor Company Head of Press and Media, explains, “they effectively became redundant. They were no longer needed for the purpose they were produced for. Very affordable four-wheeled vehicles came along and replaced the three-wheeler.” Those vehicles include Morgan’s 4-4, which began production in 1936 and eventually surpassed the Three-Wheeler in purpose and performance.

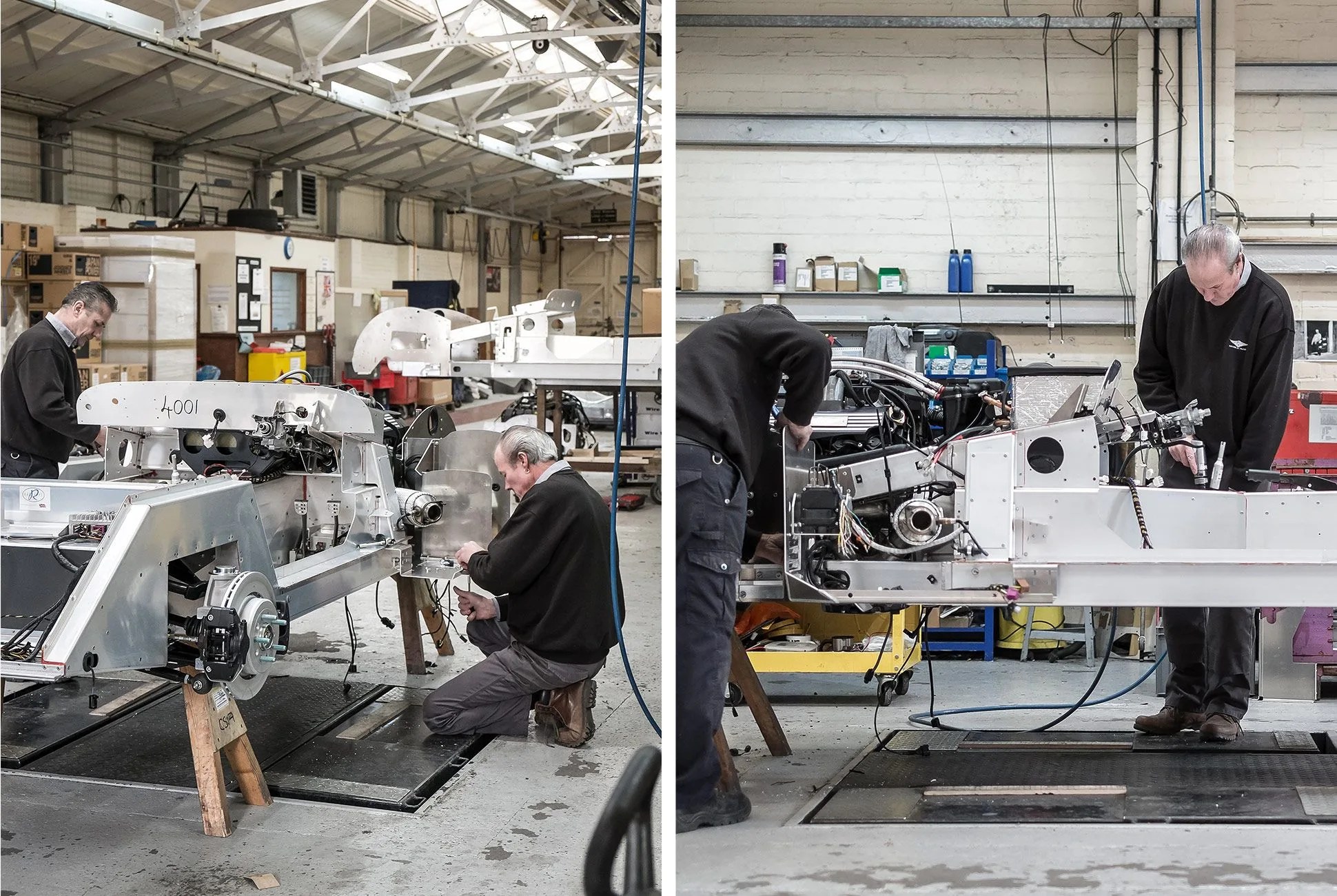

“We continued, throughout the 20th and into the 21st-century, building what we would refer to as four-wheeled proper sports cars: lightweight, a range of engine sizes, but all incredibly fun to drive; used on race tracks, trials, on the road, touring all around the world.” Like other long-standing, successful, small-batch British sports car makers, Morgan found a signature recipe and stuck with it. “We were using what were, at the time, quite common methods of manufacturing in terms of coachbuilding: using an ash frame, metal body panels and then, [later], a ladder frame chassis. That’s now incredibly unique. We’re now one of the very few car manufacturers using traditional craftsmanship methods. And that’s what’s kept Morgan very much alive.”