“Without us, you’d just have a nice ornament for your lawn,” Mary Ann Brown, Plant Communications Manager, tells me as we stand outside GM’s Tonawanda Engine plant, a 2015 Cadillac Escalade ($72,970) in the circle drive in front of us. It’s noon, and the sun’s high above Tonawanda, a small town adjacent Buffalo, NY. The Escalade beats gnomes and flamingos as lawn ornaments go, but this 5,845-pound piece of glistening lawn candy belongs on the road.

I’d driven the Escalade from New York City — a home where most see these beasts as high-end livery shuttles — up to Saratoga Springs, NY — an upper-class resort town town befitting an Escalade audience — and then on to Tonawanda. Eight hours on the road may seem like an exaggerated model of the Sunday drive, but it never felt it inside the cabin. The fourth-gen Escalade carries on the model’s 16-year tradition with supreme luxury. Front seats get both internal heating and cooling; premium kona wood and jet-black accents compliment the sleek cabin; GM’s CUE touchscreen is intuitive and responsive, and the OnStar wi-fi outperforms most hardline Internet connections, even in rural upstate New York; inlaid, triple-sealed doors and acoustic-laminate glass reduces exterior noise and fosters a tranquil cabin; and a Magnetic Ride control reads the road and adapts body motion in milliseconds.

But that was all fluff. The purpose of taking this pearly-white NYC-condo-sized road warrior to upstate is to see what sits under the hood.

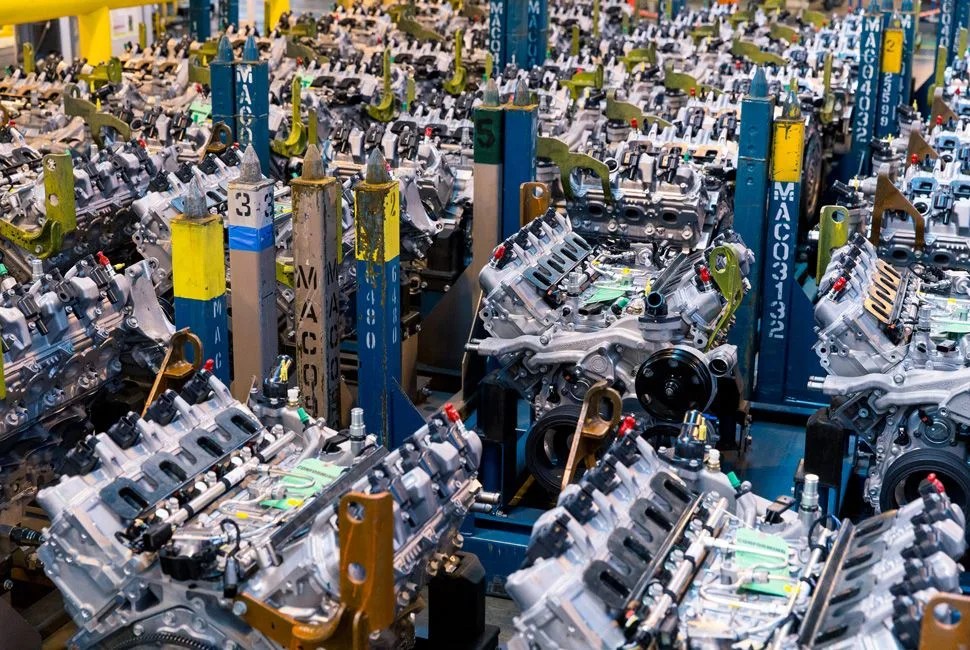

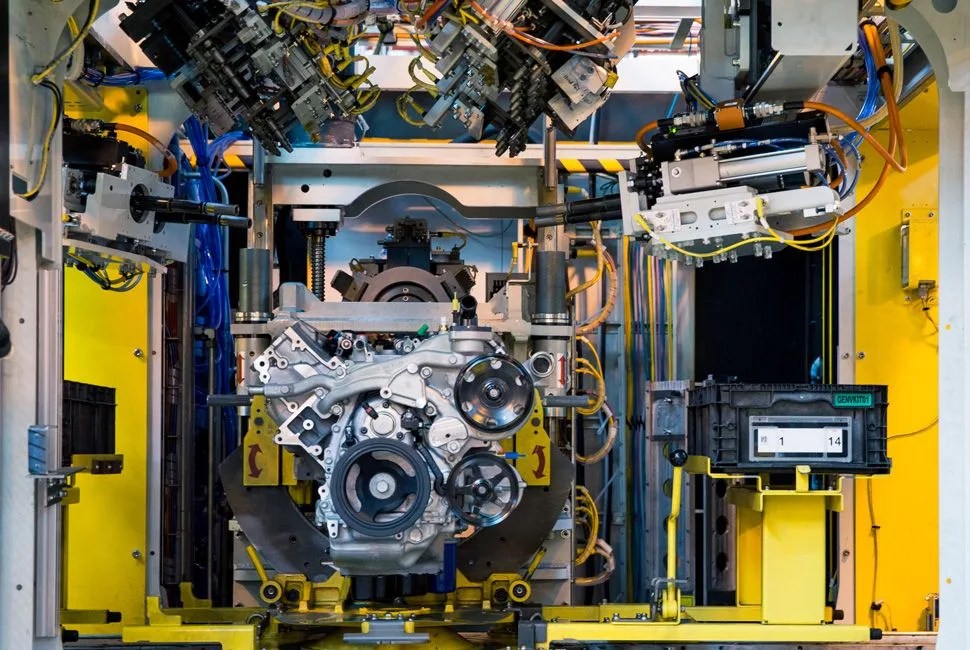

Tonawanda builds GM engines. Their factory motto is “We make ’em go.” The 6.2-liter V8 that powers the Escalade is built in the 1-million-square-foot building behind me, and Frank DiBernardo, Manager-Controls Engineering, is about to walk me through the line.

The Tonawanda factory is 77 years old. It doesn’t look it; when GM filed for bankruptcy in June of 2009, the factory was reassessed, found viable and given a facelift. After being stripped down completely, the factory’s walls were opened up, a new concrete floor laid, new equipment brought in, and production ramped up. 1,200 people were hired, and GM spent $4 million training new employees to work with the new equipment and to new standards of precision. Today, the factory runs 24 hours a day, Monday through Friday and on Saturdays. When combined with the Rochester and Lockport factories, GM employs 4,000 people in NY state. Its pillars of operation are safety + people + quality + responsiveness + cost. It makes around 540 engines a shift, 1,600 engines a day.

14 photos

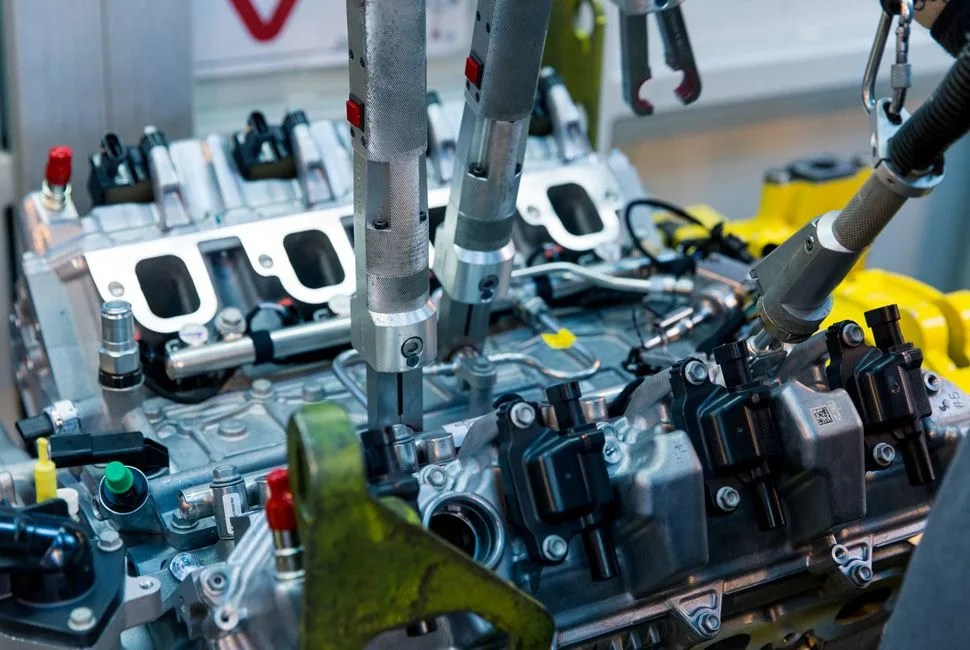

DiBernardo is a large man with a goatee, a hairline losing ground, and a slight belly that protrudes from a black GM polo shirt. He wears Wrangler jeans and Asics sneakers. He takes pride in how his engines are made, and he knows the process forward and back. He begins with RFI-IDs — data bolts — that get locked into each engine before it starts down the line. These are new to the revamped factory, and a point of pride. The bolts are identifiers, and they make the engine’s progress traceable at each step of the line.